LUMBERMENOnline.com’s Latest Industry News & Articles

Submit your company’s latest news or articleBandit offers remote controlled Kesla loaders on larger hand-fed chippers.

Bandit now offers extending Kesla loaders with radio remote controls on its Intimidator™ 21XP hand-fed chippers, giving land-clearing professionals, tree care companies and right-of-way contractors a powerful all-in-one tool to dispose of limbs and even whole trees.

“Rated as a 21” capacity chipper, the 21XP is the largest hand-fed chipper in Bandit’s fleet, so it’s built to chip heavy, large-diameter trees. Those can be difficult to quickly get to the chipper, even with a winch,” said Bandit Sales Manager Jason Morey. “The Kesla loader option increases the productivity of this machine in virtually any application.”

The Kesla loader can extend to 21 feet and grab large bundles of limbs, large individual limbs, and even downed whole trees. Using intuitive controls, the operator can guide the material quickly into the chipper to be processed in a fraction of the time it would take operators to winch.

“This option can eliminate the need for additional workers on the ground, or additional equipment brought to the jobsite,” Morey said.

When not in use, the Kelsa loader folds up on the front of the chipper where it’s out of the way, never impeding the discharge chute, or limiting access to common maintenance items.

With a rated chipping capacity of 21 inches, a huge 24.5-inch by 26-inch chipper throat opening, Bandit’s Slide Box Feed System and engine options up to 350 horsepower, the Intimidator™ 21XP is simply the ultimate hand-fed chipper. This machine has no problem processing large whole trees, and is designed for tree services specializing in large tree takedowns, land clearing operations, or any projects requiring the highest levels of production and performance.

Learn more about Bandit Industries by visiting www.banditchippers.com or by calling 1-800-952-0178.

Wood-Mizer introduces two new bandsaw blade options with 1” and 1 ¼” tooth spacing to satisfy the needs of high production, high horsepower resaw and sawmill operations. The new blade tooth spacing options further expand the industry-leading Wood-Mizer range that includes a large variety of bandsaw blades for nearly every type of sawing or resawing application.

Available in SilverTip carbon material, 1” tooth spacing blades are offered in a 10 degree all-purpose profile to saw any type of wood species. These blades are designed for high production resaw and sawmill operations that prefer 1” tooth spacing or for filing rooms that have blade maintenance equipment currently setup for 1” tooth spacing.

1” Tooth Spacing Blades

- .045 x 2”

- .055 x 1 ½”

- .055 x 1 ¾”

- .055 x 2”

Available in SilverTip carbon material, the 1 ¼” tooth spacing blades are offered in a Turbo 7 degree high-performance profile. With increased air flow and higher tooth penetration while sawing mixed species, Wood-Mizer’s exclusive Turbo 7 degree profile is tried, tested, and proven by high production, high horsepower, and high feed rate operations throughout the world. Combine this exclusive Turbo 7 profile with a wider 1 ¼” gullet to provide an ideal blade for high throughput grade resaw and sawmill operations.

1 ¼” Tooth Spacing Blades

- .045 x 2”

- .055 x 1 ¾”

- .055 x 2”

- .050 x 3”

Both 1” and 1 ¼” tooth spacing blades are now available to order in a variety of lengths to fit various sawmill and resaw brands and models. Wood-Mizer provides blade maintenance equipment and ReSharp services that are able to accommodate these new tooth spacing options.

Wood-Mizer offers an extensive range of blades with more than 100 combinations based on profile, width, thickness, tooth spacing, and alloy for any type of sawing or resawing application from green softwoods to abrasive hardwoods. For more information, visit www.woodmizer.com/blades or call 800.522.5760.

About Wood-Mizer

Since 1982, Wood-Mizer has earned the reputation as a leading wood processing equipment manufacturer with a strong legacy from its innovative sawmilling products. From forest to final form, Wood-Mizer offers an extensive line of equipment including narrowband portable and industrial sawmills, wideband sawmilling equipment, band resaws, board edgers, wood kilns, planer/moulders, firewood processing equipment, pallet recycling equipment, material handling equipment, bandsaw blades, and blade maintenance equipment for woodworking and forestry hobbyists and professionals all over the world.

Woodland Equipment recently held an open house event to mark the opening of a second location.

Woodland Equipment has been in business for more than 40 years. Ron Beauchamp Jr. succeeded his father, who still works in the business, in 2014.

Ron has expanded the business, adding new lines of equipment. Woodland Equipment became a dealer for Tigercat in 2016, serving all of Michigan and 90 percent of Wisconsin. “Tigercat is a premium design,” noted Ron, “engineered for strength and durability.”

The company’s original location is in Iron River, Michigan, on the Upper Peninsula. Ron continues to grow and expand Woodland Equipment to serve the logging industry and recently added a second location. The new location is in Gaylord, which is in the northern portion of lower Michigan.

Ron explained his reasoning. The distance from Iron River to the Mackinac Bridge, which connects the Upper Peninsula to Lower Michigan, is a little over 200 miles. “To really service the Lower Michigan marketplace,” said Ron, “I felt we needed to add a second store. Customers want you close by for parts and service, and they want to know you’re not going to fold up your tent and leave.” He and his wife are already working at the new location full-time and are in the process of moving to the area; and service personnel are traveling from Iron River to work at the new location as needed.

Ron bought an existing building in Gaylord from a construction company, and it has five service bays for servicing and repairing equipment. He is in the process of hiring full-time employees for parts and service. Ron will continue to split time between stores to foster communication and consistency, but has already hired additional staff for the Iron River location to serve the UP and Wisconsin markets.

The company held a grand opening for the new location in June that was attended by a few hundred customers and other loggers as well as key Tigercat personnel.

The Tigercat brand is proving itself in the Great Lakes region, according to Ron. “We invested time to establish a Tigercat presence. Tigercat machines are proving their performance. Now we’ve got traction.”

Tigercat has 10 manufacturing facilities in southern Ontario. They are only a five hour drive from Gaylord, noted Ron. “That’s a distinct advantage for customers,” he said.

The proximity to southern Ontario has allowed Ron to arrange group tours of the Tigercat manufacturing plants. The tours have been effective in marketing the brand, said Ron, educating and informing loggers about the design and manufacturing of the machines. “Everyone who has attended has come away with appreciation for Tigercat’s commitment to building the best machines possible. Every single customer has said the time was very well spent” he reported. The next one is scheduled after the upcoming Great Lakes trade show.

Tigercat manufactures its own parts wherever possible, noted Ron, including the skidder bogies. It gives them greater control over the quality and problem resolution process, he added. If a part fails, they can analyze their design and manufacturing processes to determine if there is a flaw and correct it. In-house manufacturing allows Tigercat to control their own destiny on quality, strength, and durability – which ultimately benefits the customer.

Woodland Equipment is also a dealer for TimberPro logging equipment as well as four manufacturers of felling heads and processing attachments: Risley, Log Max, Quadco, and Kesla.

For more information on Woodland Equipment and its product lines, visit www.WoodlandEquipment.com or call (906) 265-9904 for the Iron River location.

After more than 15 years providing superior cellular device repair, as well as cellular amplification products, to customers throughout the Upper Midwest, the name has been changed to Reach Amplification. According to founder and president, Ryan Kaiser, the move will allow his team to focus solely on improving the reach of customer cellular signals. Complete Cellular Services will become Complete Cellular Repair, owned and managed by longtime Lead Technician Wayne Shultz with no interruption in service. In addition to improved product focus and customer service, the move also will allow Reach Amplification to offer cellular amplification products nationwide as well as expand its product line to include more remote wireless solutions. We create a custom solution for your buildings (job trailers, campers, residential or commercial) and custom Mobile Booster packages to fit your needs. One example is the new SpyPoint cellular trail cams that provide a way to monitor and protect equipment in remote areas, as well as offering sportsman real-time images of their favorite hunting spot.

If you’ve ever wondered if there was a way to amplify your signal, you should call Reach Amplification today at 715-298-4414 or visit www.ReachAmplification.com

Responding to customer demand for a compact high production commercial firewood splitting system led Wolfe Ridge Manufacturing to design the new Compact Commercial line. Like every Wolfe Ridge splitter, innovation was at the heart of the new design. With features like Run from Either Side and tow from either end you can fit this unit in the smallest woodlots, barnlots or even backyards. Available in 22, 28 or 35 ton models with standard features such as: log lift, outfeed sorting table, 4 way splitting wedge and Honda power.

Wolfe Ridge owner, Chris Wolfe stated that “our goal with the Compact Commercial line was to trim the needed footprint without sacrificing quality and production… in our extensive testing program we were able to produce up to two full cords per hour...”

If you need a small wood splitter that packs a large punch at a very attractive price point, you owe it to yourself to check out the Compact Commercial line from Wolfe Ridge Manufacturing at www.WolfeRidgeMFG.com or call 715-598-7790.

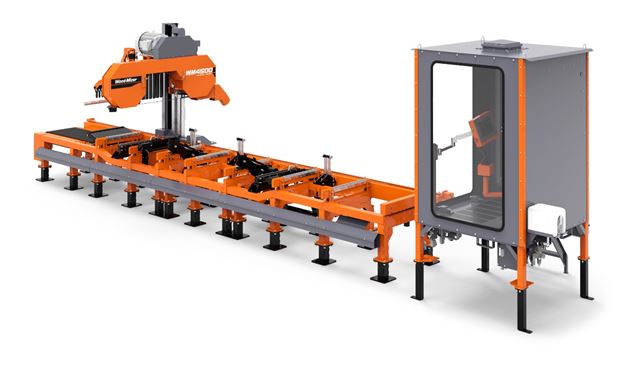

Wood-Mizer introduces the WM4500 industrial sawmill featuring several structural and performance enhancements to the sawmill head and bed for improved sawing productivity. As Wood-Mizer’s next generation flagship industrial sawmill, the all-new WM4500 continues a long tradition of providing commercial sawmilling equipment solutions throughout the world.

Featuring many benefits of Wood-Mizer’s world renowned industrial sawmill range, the WM4500 can be used to breakdown logs for further processing or to saw boards, grade or dimensional lumber. Alongside the complete line of Wood-Mizer sawmills, the WM4500 capitalizes on thin-kerf blade technology to produce accurate lumber while reducing capital, material, labor, energy, and maintenance costs.

WM4500 Features

Power

- 30 HP Electric (22.4 kW)

Cutting Capacity

- 40” (1 m) log diameter

- 21’ (6.4 m) cutting length with board removal

- 32 ¼” (819 mm) width of cut and 16” (405 mm) depth of cut

Blade Specifications

- 2” (51 mm) blade width capacity with steel band wheels

- 3” (76 mm) diameter blade guide rollers

Introductory Price

- Starting at $105,995 USD

“Wood-Mizer is dedicated to providing the best-in-class sawmilling equipment throughout the world,” said Greg Bacon, Wood-Mizer Sales Director. “The WM4500 is the result from years of customer feedback and rigorous testing to satisfy the needs and preferences of high-production operations.”

Key innovations of the WM4500 sawmill bed include reinforced dual-rod side supports, heavy-duty angled bed rails, 21’ cutting length with board removal, pull down cinch clamps for cants, and off-feed conveyor & roller with suspension. The robust sawmill head includes 2” blades with steel wheels, stronger head, mast, and strain system, 5HP feed motor, larger up/down gearbox, high pressure blade lubrication system, adjustable material drag back, modular toeboards, and durable 3” diameter blade guide rollers.

The WM4500 industrial sawmill is now available to order in North and South America. For more information, visit www.woodmizer.com or contact your local Wood-Mizer representative.

About Wood-Mizer

Since 1982, Wood-Mizer has earned the reputation as a leading wood processing equipment manufacturer with a strong legacy from its innovative sawmilling products. From forest to final form, Wood-Mizer offers an extensive line of equipment including narrowband portable and industrial sawmills, wideband sawmilling equipment, band resaws, board edgers, wood kilns, planer/moulders, firewood processing equipment, pallet recycling equipment, material handling equipment, bandsaw blades, and blade maintenance equipment for woodworking and forestry hobbyists and professionals all over the world.

Wood-Mizer introduces the FS150 dual action 20 ton log splitter designed for homeowners and small landowners looking for an affordable and highly durable American-made log splitter. The FS150 log splitter expands the Wood-Mizer firewood processing equipment range that includes gas powered and skid steer commercial log splitter models ranging from $6,995 to $13,995 USD.

Starting at $2,595 USD, the FS150 combines a 7HP Kohler gas engine with 20 tons of splitting force to split hardwood and softwood logs up to 24” long. The log table height is 30” from the ground to provide a comfortable working height for the operator and the convenient operator panel features intuitive left/right controls for the log splitting wedge. Once a log is loaded for splitting, the 8 ½” high carbon steel wedge splits wood in both left and right directions for increased speed and efficiency. This unique two-way design can double firewood production compared to traditional one-way wood splitters. During the splitting operation, two side trays catch material for additional splitting or for convenience in handling wood when stacking. Featuring a compact design for easy storage and mobility, the FS150 also includes a standard trailer with a 2” hitch that is towable at speeds up to 45 mph.

FS150 Log Splitter Specifications

Introductory Price

• Starting at $2,595 USD

Features

• 7HP Kohler gas engine

• 20 ton splitting force

• Dual action splitting wedge

• 7 second cycle time

• Trailer for towing up to 45 mph

“Wood-Mizer is committed to providing landowners and homeowners the equipment necessary to process logs into boards, slabs, firewood, and other marketable wood products,” said Greg Bacon, Wood-Mizer Sales Director. “The FS150 is an American-made, affordable log splitter for residential use that stands up to the high-quality standards that is synonymous with Wood-Mizer wood processing equipment throughout the world.”

The FS150 dual action log splitter comes with a 1-year warranty, ships fully assembled on a single pallet, and is backed by the same legendary service, quality and safety features shared by the entire family of Wood-Mizer wood processing equipment. The FS150 log splitter is now available to order in North America, South America, Asia and Oceania. Visit woodmizer.com/logsplitters for more information.

About Wood-Mizer

Since 1982, Wood-Mizer has earned the reputation as a leading wood processing equipment manufacturer with a strong legacy from its innovative sawmilling products. From forest to final form, Wood-Mizer offers an extensive line of equipment including narrowband portable and industrial sawmills, wideband sawmilling equipment, resaws, edgers, kilns, planer/moulders, firewood processing equipment, pallet recycling equipment, material handling equipment, bandsaw blades, and blade maintenance equipment for woodworking and forestry hobbyists and professionals all over the world.

The most versatile firewood processor on the market is ready. Business owners around the world had their say and Hakki Pilke listened. The end result is an efficient, durable and innovative one-man firewood factory.

Hakki Pilke 50 Pro is the king of firewood processors; it is the most efficient industrial model on the market. 50 Pro continues a strong tradition. Its predecessors include Easy 50s and BigX47, both of which are some of the most popular professional machines in their category worldwide. Thanks to knowledgeable and active users, the new model is tailored to fulfil even the most demanding customer needs.

50 Pro cuts and splits so efficiently that it can be described as a one-man firewood factory. The easy-to-use HakkiCut™ user interface streamlines cutting and improves working conditions.

“We truly value ergonomics. With the HakkiCut™, the user can easily control the machine with the two buttons on the joystick. This helps maintain good working position, with no compromises on efficiency,” says Development Manager Timo Jussila from Hakki Pilke.

HakkiCut™ automatically optimises cutting speed, and the cutting itself is performed by simply pushing a button. Thanks to the delay-free HakkiSplit™ cutting system, material flow remains smooth with peak productivity.

JOIN THE WINNING TEAM

Forstunternehmen Reith is a German company that produces firewood. Its owner Dietmar Reith had the opportunity to test the 50 Pro before anyone else.

“The excellent new measuring device combined with faster splitting compared to the previous model,” Reith says, when asked about the features of the new 50 Pro that make his work easier.

Dietmar Reith has been a customer of Hakki Pilke for nearly twenty years. This means that he is one of the tens of thousands of users that are part of the winning team.

“To us, the Join the Winning Team slogan means that we are always there for our customers and partners. We ensure that business owners have the use of the most modern firewood processor in the business, while providing spare parts for old models,” says Managing Director Anssi Westerlund from Hakki Pilke.

Being local is also important. The fact that the salesperson understands the challenges associated with the climate and wood species in the area is crucial. The Hakki Pilke team is always local: the company has representatives in 34 countries around the world and they stick up for their own.

“Our importers are committed to our values and understand the importance of the team,” Westerlund says.

DURABLE, SAFE AND EFFICIENT

The product developers at Hakki Pilke focused on the durability of the machine. The number of mechanical wear parts has been minimised in the new model. The AC 10 chain tensioner and revamped hydraulics are examples of the multitude of changes that can double the service life of wear parts and make the machine even more efficient than before.

The need for maintenance has also been minimised: chain replacement can be performed without tools, and instead of several minutes, the task can be performed in roughly twenty seconds.

The new machine knows no bounds, but processes all types of wood regardless of its hardness or crookedness. No wonder, as Hakki Pilke has revolutionised the market with several innovations and firewood processors for three decades and counting.

“Development starts in the field. It is down to our team members, i.e. users, that the Hakki Pilke 50 Pro is the most versatile firewood processor on the market.”

ABOUT MAASELÄN KONE LTD

Hakki Pilke has sold over 30,000 units in over 35 countries. In the 1990s, model 1X37 revolutionized the firewood industry becoming the world’s most sold firewood processor. Today the Hakki Pilke brand is known for its excellent after-sales services and state of the art performance and reliability. Easy mobility and fast set up makes Hakki Pilke processors great for both indoor and outdoor use.

For more information, visit our new website http://hakkipilkeusa.com/ or https://hakkipilke.fi/en/

Wood-Mizer will sponsor an urban wood seminar, "The Urban Wood Revolution is Now! Come Join the Movement," on Friday, August 24 at the International Woodworking Fair in Atlanta, GA.

The seminar will focus on the environmental and economical benefits of utilizing locally sourced urban wood while providing practical instruction and networking opportunities for sawyers, woodworkers, lumber suppliers, and lumber buyers.

Urban trees are used for lumber in order to make better use of wood from sources like our own yards, parks, and even near our city streets. Every urban tree used for lumber is one less tree that must be cut from our forests and one less piece of green waste that would otherwise be dumped in our landfills.

According to IWF, the seminar will also address:

> The unique "source local/buy local" marketing appeal of urban wood products and the interesting stories they tell

> The environmental advantages of utilizing urban wood

> How to find local sources of urban wood

> How to join or start a local urban wood network

> A Q&A session with an expert panel

The main speaker for the seminar is Jennifer Alger, CEO of Far West Forest Products of Sheridan, CA, and president of the newly founded Urban Salvaged & Reclaimed Woods, the first urban lumber trade network on the West Coast.

Dwayne Sperber will also be speaking at the event. Dwayne is the Wisconsin state lead for the Urban Wood Network, and the owner and founder of Wudeward Urban Forest Products, which supplies lumber to architects, designers, and builders.

"Throughout the past decade, Wood-Mizer has seen a major influx of successful businesses who are utilizing urban-sourced wood for their sawmilling operations and we are proud to manufacture a product that enables small businesses to be profitable with an underutilized resource," explains Wood-Mizer COO Darryl Floyd. "While Wood-Mizer has been educating woodworkers about the positive environmental and economic impact of urban wood for years, the Urban Wood Seminar at IWF 2018 will be another step forward in saving more trees from going into the waste stream."

Wood-Mizer is dedicated to sustainable forest management and the urban sawmilling movement. The company recently developed an Urban Sawmilling Video Series highlighting businesses in the USA and Canada who are using locally sourced and salvaged urban timber to make a difference in the wood industry, where many of the hardwoods and softwoods we love are burned, buried, ground, or simply thrown away.

Wood-Mizer has also published a guide to urban milling called "Salvaging, Sawmilling, and Marketing Urban Wood" which can be downloaded here.

The Urban Wood Network, along with Wood-Mizer, recognizes the need for sustainable forestry practices and has joined businesses and individuals in the Midwest to promote urban wood utilization. Part of UWN's mission is to "build a common understanding, language, commitment, and eventually, brand for the urban wood marketplace."

The Urban Wood Seminar is free of charge, but advanced registration is required to guarantee a seat. Learn more and register here.

About Wood-Mizer

Since 1982, Wood-Mizer has earned the reputation as a leading wood processing equipment manufacturer with a strong legacy from its innovative sawmilling products. From forest to final form, Wood-Mizer offers an extensive line of equipment including narrowband portable and industrial sawmills, wideband sawmilling equipment, resaws, edgers, kilns, planer/moulders, firewood processing equipment, pallet recycling equipment, material handling equipment, bandsaw blades, and blade maintenance equipment for woodworking and forestry hobbyists and professionals all over the world.

OMAHA, NE – July 17, 2018

DMSi Software announces its partnership with TallyExpress, the revolutionary lumber tally app.

TallyExpress represents a major shift in end tally technology. While most solutions rely on lasers and specialized equipment, TallyExpress runs on an Android phone or tablet and is simple for users to navigate. It puts tally technology within reach of hardwood businesses deterred by the complexity and cost of laser-based systems.

DMSi’s leadership sees TallyExpress as a natural complement to its line of software solutions for the lumber industry. “We’ve spent decades developing software to help our customers grow their businesses,” said Henry German, DMSi’s market teams manager. “When we saw what TallyExpress can do, we knew immediately it was a technology breakthrough for the industry. We’re bringing this product to market because it is the right solution for our customers’ futures.”

TallyExpress is available as a stand-alone product or as an integrated component of Agility, DMSi’s inventory management system.

About TallyExpress

TallyExpress was developed by Fordaq, a technology company providing solutions to the global forestry and wood products industry. DMSi is the official reseller of TallyExpress to North American markets. Learn more at tallyexpress.com or by calling (402) 996-2706.

About DMSi Software

DMSi provides the leading business software for the lumber and building materials industry. Their Agility ERP system includes integrated accounting, sales, purchasing, and remanufacturing, as well as CRM, eCommerce, and mobile sales solutions. Learn more at dmsi.com.

West Plains Resaw System Mini Edger w/10" wide capacity on the infeed and outfeed with a 1 hp feed motor & 15 hp arbor motor running a 2 7/16" arbor with 2 12" diameter 12 tooth saw blades able to handle material from 1/2" to 1 1/2" in thickness. Custom collar spacing gives the ability to reclaim #2 6" decking lumber into #1 4" decking lumber or reclaim thicker lumber up to 1 1/2" into decking or stringer material. Optional 12" capacity and feed speed control available.

Meadows Mills, Inc. of North Wilkesboro, NC is proud to unveil its new website, created by LumbermenOnline.com, the sister company of Lumbermen’s Equipment Digest. The transition to the new website allows Meadows’ customers to browse the same equipment and information clearly with the mobile friendly design that adjusts to the users’ device. With the wide range of high quality, low cost equipment Meadows is known for, easy navigation and grouping of products such as carriages, edgers, and material handling equipment was overdue.

Nearly 120 years of history and the ever-changing demands of innovation are wrapped up in every Meadows’ product – incorporating both in the website was essential. Many company history pages reference a generation or two, Meadows Mills’ begins in 1900 and covers multiple owners, acquisitions and how they’ve produced over 50,000 machines with its detailed navigation back in time. Whether you’re in the market for new equipment or not, it’s a must read.

Visit the new MeadowsMills.com, and you’ll be able to easily browse their entire sawmill equipment line up, check out their stone burr mill equipment, and find information on their new ag implements. The next time you’re upgrading, replacing or building a complete new system, start your search by going to MeadowsMills.com!

.gif)