LUMBERMENOnline.com’s Latest Industry News & Articles

Submit your company’s latest news or articleSawmill Supplies & Equipment, LLC of Sarepta, LA is proud to unveil its new website, created by the LumbermenOnline.com team! The new website allows for customers to quickly find equipment that fits their needs in an easy to browse, mobile design. Perspective customers can easily find options, general specs, videos and large, clean pictures of equipment to make their equipment search easier.

Sawmill Supplies & Equipment LLC is owned and operated by the Morgan family, which brings three generations of experience, innovation, and high standards to their equipment line up, including the Original Low-Profile Band Resaw. Holding this branding as a long-standing staple in the industry is a continued focus for Sawmill Supplies and is explained throughout the new website. Equipment made by the Morgan’s has always been simple in design, easy to operate and maintain, and saves you big on labor – the new website follows right in line!

If you’re looking for the Original Low Profile Band Resaw, Multi-Head Resaws, Trim Saws, Notchers, Dedusters, Edgers and MORE - Check out the new www.SawmillSupplies.net!

August 18, 2019 – Dorchester, WI – Following months of extensive design, development and testing Brute Force Manufacturing unveiled the new CS20-24HD circular saw firewood processor at the NYS Logger Field Days in Boonville, New York to rave reviews. Buyers at the show were impressed with the CS20-24HD’s extremely fast cutting and cycle times, putting it in the same class as machines requiring nearly double the investment. Featuring a low maintenance replaceable tipped 48 inch carbide circular saw, improved feed tray design and sturdy rigid frame to providing long service life. The CS20-24HD is powered by a fuel efficient Kohler 74HP Tier 4 liquid cooled diesel engine, that includes a 3 year manufacturer’s warranty and provides superior power for maximum production. Available with your choice of 4, 6 or 8 way wedge, it was exhibited at the Boonville event with the new optional box wedge designed to produce smaller uniform wood that is ideal for stove use, retail, package and specialty restaurant woods.

The CS20-24HD, like every Brute Force firewood processor lives up to their company slogan “INVEST LESS – PRODUCE MORE”. For complete details on this and other quality firewood production, packaging and handling machinery visit www.bruteforcemfg.com or call 715-678-0037.

Wood-Mizer introduces the LX250 wide slab sawmill designed for sawyers and woodworkers that need to saw massive slabs and boards up to 54 ½” wide. Joining Wood-Mizer’s world-leading range of portable sawmills, the LX250 is the second largest capacity sawmill offered by the company, with the popular WM1000 sawmill capable of sawing 67” diameter logs.

Built in the USA, the LX250 is a robust sawmill with powered saw head controls for ease of operation, adjustable presets for quick and accurate blade height control, and a massive 54 ½” width of cut ideal for sawing wide, live edge slabs.

A key innovation of the Wood-Mizer LX sawmill series includes the rigid LX Frame sawhead tower that holds the control panel, engine, and the sawmill head. Designed to accommodate a larger width and depth of cut, the LX Frame travels on twin parallel hardened steel rails on the bed and allows the operator to have better visibility while sawing.

LX250 Wide Slab Sawmill Features

• Starting at $25,995 USD

• 55” log diameter with 54 ½” max width of cut and 13' length of cut

• Optional 5’ bed extension available for 18’ max length of cut

• Powered saw head up/down & forward/reverse with dual power feed chain system

• Adjustable preset board thicknesses to quickly and accurately control blade height

• 38HP gas engine or 15HP 3-Phase electric motor

• Built in the USA

“Wood-Mizer is dedicated to providing best-in-class sawmill and wood processing equipment that fits the diverse needs of our customers,” said Greg Bacon Sales Director. “With the growing demand of wide, live edge slabs and boards, the LX250 provides customers a large capacity sawmill at an affordable price that can efficiently produce these high-value wood products.”

Starting at $25,995 USD, the LX250 Wide Slab Sawmill is now available to order in North America. For more information, visit www.woodmizer.com or contact your local Wood-Mizer representative.

About Wood-Mizer

Since 1982, Wood-Mizer has earned the reputation as a world-leading wood processing equipment manufacturer with a strong legacy from its innovative sawmilling products. From forest to final form, Wood-Mizer offers an extensive line of equipment including narrowband portable and industrial sawmills, wideband sawmilling equipment, band resaws, board edgers, wood kilns, planer/moulders, firewood processing equipment, pallet recycling equipment, material handling equipment, bandsaw blades, and blade maintenance equipment for woodworking and forestry hobbyists and professionals all over the world. Visit woodmizer.com for more information.

CHATTANOOGA, Tenn., July 29, 2019 — Komatsu America Corp., a leading global heavy equipment manufacturer, recently launched its new XT-5 Series of Track Feller Bunchers. Models include the XT430-5 (non-leveling), XT445L-5 and XT465L-5, which replace the prior XT-3 Series machines.

The XT-5 Series ranges in operating weight from 66,359 lb. (30,100 kg) to 74,516 lb. (33,800 kg) and features a new, more powerful fuel-efficient EPA Tier 4 Final engine, gull-wing style engine hood, increased lift capacity, heavy-duty undercarriage, redesigned and relocated cab, new hydraulic and cooling systems, forestry-specific guarding and KOMTRAX® telematics system technology.

“We have been systematically gathering and analyzing voice-of-the-customer input to define our next generation of feller bunchers,” said Mitsuhiro Utsumi, vice president, forestry product marketing, Komatsu America. “This new XT-5 Series represents the culmination of translating that entire input into feller bunchers which truly meet the needs of today’s demanding loggers,” Utsumi said.

Performance & Productivity

The new 310 peak hp (231 kW), Cummins QSL9 9-liter engine provides more horsepower, torque and displacement and lowers fuel consumption by as much as 10%, due to advanced engine and hydraulic system control designs. Lift capacities at full reach lift have been significantly increased, and the XT465L-5 now readily operates the Quadco 24-inch (610 mm) cutting capacity disc saw heads.

Operator Comfort & Convenience

The state-of-the-art, fully-certified, Komatsu forestry cab has been relocated to the left of the boom for industry commonality. Cab design changes provide superior lines-of-sight to each track. A standard rearview monitoring system further enhances the operator’s view. Eleven (11) LED lights provide superior visibility for night operations.

Komatsu’s highly intuitive, IQAN-MD4 digital control system programming allows up to three (3) different operators to program their individual control patterns for increased multi-operator productivity. An IQANsync mobile phone app is available to allow remote access to perform IQAN system functions.

Reliability & Durability

New more rugged Komatsu undercarriages significantly increase service life including:

• Rugged, 8.5" track chain links are stronger at resisting "twist"

• Track rollers and idler bushings are made of high-density material allowing longer wear

• The XT445L-5 and XT465L-5 have larger track guard roller side openings to minimize mud packing and facilitate cleaning

• The XT465L-5 has 9 vs. 8 rollers for improved load distribution. Track length has been extended to the rear by 5.3” (135 mm) for improved steep slope stability

• The XT445L-5 and XT465L-5 have a reduced track slider angle producing 30% lower contact pressure for reduced wear

• All final drives have a new triple labyrinth floating seal housing to protect the seal against mud packing

Larger capacity, hydraulic piston pumps for the implement, attachment and disc saw operate at 500 rpm lower speed, while delivering high performance flow. Each pump has a pre-charged (pressurized) suction inlet to reduce cavitation risk. A robust forestry-specific guarding system covers the boom, arm and rear hydraulic tubes and hoses to provide superior protection and shed debris.

The totally new high capacity cooling system features a large radiator, charge air cooler and hydraulic cooler. All coolers have been relocated to the rear of the machine to minimize debris buildup. Separate radiator and hydraulic oil cooler fan controls provide the cooling needed to maintain the required temperatures. Both fans have an auto-reversing function to help purge debris and maintain cooling efficiencies.

Ease of Maintenance

A new gull-wing style engine hood folds down to provide an elevated service work platform. Four (4) other service doors swing wide to provide excellent service access. An innovative new hydraulic tank design features two (2) tanks, which require 55% less total hydraulic oil (a refill requires only 45 gallons = 171L). The attachment control valve has been relocated from the main control valve to the arm for ease of service.

Komatsu’s exclusive KOMTRAX remote equipment monitoring and management telematics system is standard. It utilizes highly reliable, satellite-based technology to transmit valuable information such as location, utilization and maintenance records to a PC via an internet website. KOMTRAX provides advanced machine troubleshooting capabilities by monitoring machine health and issues caution and abnormality alerts. This information serves as a valuable tool for scheduling preventative maintenance and service. There is no subscription fee for the life of the machine.

Komatsu America Corp. is a U.S. subsidiary of Komatsu Ltd., the world’s second largest manufacturer and supplier of earth-moving equipment, consisting of construction, mining and compact construction equipment. Komatsu America also serves forklift and forestry markets. Through its distributor network, Komatsu offers a state-of-the-art parts and service program to support its equipment. Komatsu has proudly provided high-quality reliable products for nearly a century. Visit www.komatsuforest.us and www.komatsuamerica.com for more information.

Irma, Wisconsin - Firewood Automation president, Don Liebelt, announced recently that Firewood Automation has become the new Hakki Pilke distributor and dealer for the upper Midwest region, including Wisconsin and adjoining states with expansion opportunities both west and south. Hakki Pilke is one of the world’s leading manufacturers of high quality, compact, low cost and profitable firewood processing and handling machinery. The addition of Hakki Pilke will augment Firewood Automation’s product line providing firewood splitters and processors for the homeowners and ranchers, specialty producers and high volume professionals alike.

For sales, service, parts or to inquire about dealer opportunities within the upper Midwest region Firewood Automation is your connection for Hakki Pilke Products! For more information, call Firewood Automation at 715-360-6292 or visit www.Firewood-Automation.com.

The Palax C750 revolutionizes firewood processing with its unbelievable speed and power. The processor comes with a 750 mm hard-tip blade that can cut up to 11" diameter wood. This is one of the fastest processors in its size on the market. The C750 has a excellent log flow from the in-feed conveyor to the discharge conveyor. The rear part of the machine has been made wider, making it easier for the wood to travel in the groove. With a robust splitting wedge and improved log clamp the processor is very comfortable and safe to operate.

An in-feed conveyor and a 14 ft swinging discharge conveyor come as standard with the processor. The processor guarantees a brisk working pace due to its automatic high speed valve maximizing the splitting speed. The debris grate of the splitting groove collects any debris created from the splitting, resulting in clean and easy-to-dry wood.

Equipped with lubed-for-life ball bearings the machine operates precisely, easily and virtually without maintenance. Also the chute is equipped with a sensor so that even a small log activates the splitting motion.

Automatic tightening of the V-belts keeps the angular gear belts at the correct tightness reducing strain on the transmission and significantly extending the service life of the belts.

The height adjustment of the wedge is stepless, easy-to-operate and reliable. The wedge is equipped with a quick-release.

The C750 is available as a PTO tractor driven. PTO powerpacks available.

Choose from a Pro or a Pro+ model.

Add a life Midi log deck to complete the setup.

C750 Pro and Pro+ features

o Automatic high-speed valve

o Automatic V-belt tensioning

o Connection for additional infeed roller/log deck

o Adjustable log length stopper

o In-feed conveyor 7.9" x 78.75"

o Folding and swinging discharge conveyor

o Adjustable cutting speed

o Hydraulic joystick control

o Hydraulic splitting wedge adjustment

o Hydraulic log clamp

o Conveyor speed adjustment

C750 Pro+ also features

o PowerSpeed Cylinder for optimized splitting: Automatically adjusts splitting force and speed

More information on the C750 available at www.hakmet.com or 1-800-361-2288

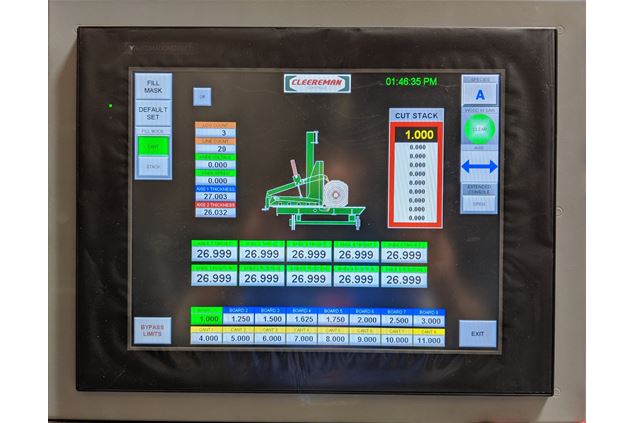

Newald, Wisconsin – After decades of working with the leading setworks and control companies, Cleereman Controls was officially founded in April 2019, to build upon parent company, Cleereman Industries’ 64-year history of providing simple and innovative sawmill machinery backed by legendary customer service. Continuing in that tradition, a first-class team was assembled with Stefan Dracobly as president and Dan Tooke as Senior Optimization Engineer. Stefan formerly served as Vice President of Engineering at Lewis Controls bringing over 16 years of hands on experience integrating technology into the sawmill industry. Dan brings 23 years of experience, serving as a software engineer for Lewis Controls and Columbia Vista Corp and most recently at Maxcess Tidland as Controls Group Leader/Software Lead Engineer.

Cleereman Controls mission is simply to provide Cleereman customers with the long-term security of knowing that product quality, performance and service is insured.

Programming and software development will take place at our Vancouver, Washington office while panel construction and control testing will be conducted at the Cleereman Industries facility in Newald, Wisconsin. Cleereman Controls is currently offering complete systems for proportional, linear positioning and full scanning with your choice of BOF and MOF solutions for both new Cleereman installations as well as replacement and upgrading of existing systems. Recently installed Cleereman Controls systems include J.W. Perry Lumber in Caneyville, Kentucky and Soapstone Lumber in Peach Bottom, Pennsylvania with six additional systems presently in production.

Wood-Mizer introduces Heicor Enterprises, LLC as their industrial authorized sales center in the Pacific Northwest. Heicor will provide all industrial products along with select professional products from Wood-Mizer. Wood-Mizer Oregon, the established branch office near Portland, Oregon, will continue to provide sales and service for Wood-Mizer professional sawmill equipment and blades in the area.

In addition to their world-leading portable sawmill equipment, Wood-Mizer’s equipment line has grown significantly and now includes machinery for the pallet industry, remanufacturing operations, cabinet and millwork shops, small log sawmill processing systems, headrigs, multirips, and sawmill systems that can produce tens of thousands of board feet of lumber per shift. “Wood-Mizer is committed to serve the needs of hobbyist, professional, and industrial-level wood processing clients throughout the world,” said Greg Bacon, Wood-Mizer Sales Director. “It became apparent that Heicor was the best choice to represent Wood-Mizer industrial products in the Pacific Northwest because of their experience and industry knowledge. We’re confident that Heicor can successfully represent Wood-Mizer in a way that is beneficial for both our company and our customers for years to come.”

Located in Monmouth, Oregon, Heicor Enterprises was founded in 2016 by Glen Heiner and Kevin Corder who both have extensive experience with Wood-Mizer. Kevin spent 27 years at Wood-Mizer and was the head of the Industrial Products Division, and Glen was an Industrial Sales/Service Specialist at Wood-Mizer for more than a decade. Glen also has experience on the user side as the owner of Portland Specialty Lumber, a millwork firm in Portland, Oregon.

Kevin Corder, President of Heicor Enterprises, said “We are very excited to become an industrial sales center for Wood-Mizer. Glen and I are both former long-time employees and it’s great to be ‘back in the saddle’ again! We are eager to present Wood-Mizer machines as a solution to many of the needs and opportunities in this region. We know the function and quality of these products along with the legendary support will fit well into the markets we will serve.”

For more information, contact Heicor Enterprises at 971-271-8070, or by email at [email protected].

About Wood-Mizer

Since 1982, Wood-Mizer has earned the reputation as a world-leading wood processing equipment manufacturer with a strong legacy from its innovative sawmilling products. From forest to final form, Wood-Mizer offers an extensive line of equipment including narrowband portable and industrial sawmills, wideband sawmilling equipment, band resaws, board edgers, wood kilns, planer/moulders, firewood processing equipment, pallet recycling equipment, material handling equipment, bandsaw blades, and blade maintenance equipment for woodworking and forestry hobbyists and professionals all over the world. Visit woodmizer.com for more information.

Halverson Wood Products is proud to announce that their long awaited HWP-125GS Grapple Saw is now available! This saw comes to you from the same people that provide the HWP-120, and HWP-140B Firewood Processors.

The new Grapple Saw is perfect for those that have outdoor boilers, that only need to cut their firewood to length, and not have it split. It is also useful for those that have large diameter logs that are too large to fit on our normal processors. The Grapple Saw also works great for storm clean up, where trees have been blown over, allowing the Grapple Saw and skid steer to do all the work!

To use the Grapple Saw, logs are picked up with the grapple, the operator engages the chain swathe, and the log is cut. The log or logs are put down, the skid steer moves over, picks them up again, and cuts them again. For longer wood that fits most boilers, the logs only have to be cut twice.

For more information on this new Grapple Saw or our other firewood processors, please check out our website at www.halversonwoodproducts.com, or call us at 218-587-2065.

About: Halverson Wood Products’ Grapple Saw and other firewood processors are proudly built and assembled at their factory in Pine River, Minnesota.

At the Forest Products Equipment Expo 2019 in Atlanta, Georgia, USA, Wood-Mizer will display two new sawmills including the high-production WM4500 industrial sawmill and the wide capacity LX250 sawmill, in addition to other professional sawmilling equipment.

Visitors to Wood-Mizer Booth 1039 at the Forest Products Equipment Expo 2019 at the Georgia World Congress Center will be met with one of the largest displays of forestry and wood processing equipment at the Expo. Wood-Mizer’s industrial sawmilling equipment will be represented which includes the company’s new flagship WM4500 industrial sawmill. Continuing Wood-Mizer’s tradition of providing commercial sawmilling solutions for high-production lumber processing operations through the world, the WM4500 includes many key innovations to the sawmill head and sawmill bed for enhanced durability and dependability. In addition, the new LX250 wide capacity sawmill with a 54 ½” width of cut will be displayed at the event. Additional products including the new HR250 twin band horizontal resaw, EG400 industrial board edger, and more professional sawmilling equipment will be represented at the event.

“The Forest Products Equipment Expo in Atlanta gives Wood-Mizer the ability to showcase two of our newest sawmills alongside our industry-leading equipment range,” said Darryl Floyd, Wood-Mizer North America President. “The innovations that have become the WM4500 industrial sawmill and the LX250 wide capacity sawmill both represent our commitment to providing sawmill equipment that fits the various needs of sawmillers throughout the world."

According to the Expo, more than 100,000 square feet of the Georgia World Congress Center will be dedicated to showcase a broad range of forestry and wood processing equipment during the 3-day exposition. Since 1950, the Expo has provided the forest products industry with a quality venue to discuss trends, discover new technologies and focus on manufacturing success.

About Wood-Mizer

Since 1982, Wood-Mizer has earned the reputation as a world-leading wood processing equipment manufacturer with a strong legacy from its innovative sawmilling products. From forest to final form, Wood-Mizer offers an extensive line of equipment including narrowband portable and industrial sawmills, wideband sawmilling equipment, band resaws, board edgers, wood kilns, planer/moulders, firewood processing equipment, pallet recycling equipment, material handling equipment, bandsaw blades, and blade maintenance equipment for woodworking and forestry hobbyists and professionals all over the world. Visit woodmizer.com for more information.

Superior, Wisconsin –

Barko Hydraulics, LLC (Barko), leading developer, manufacturer and distributor of innovative heavy equipment solutions for the forestry, site prep and material handling industries, will be attending the 2019 Mid-Atlantic Logging & Biomass Expo, Friday-Saturday, May 3-4, 2019 in Laurinburg, North Carolina with dealer John Woodie Enterprises. Barko invites conference attendees to visit the Barko team and check out the company’s latest products at the Barko/John Woodie Enterprises booth.

“We are excited to debut our new product at the Mid-Atlantic Logging & Biomass Expo,” said Steve Talaga, Director of Marketing at Barko. “Our 830B Wheeled Feller Buncher was designed to increase productivity and reduce operator fatigue during long working hours.

Barko’s wheeled feller bunchers are engineered and purpose built using extensive input from experienced forestry professionals who know and live the job. Equipped with smooth, responsive controls, Barko wheeled feller bunchers operate with exceptional performance and feature optimized weight distribution which ensures maximum stability when handling large loads.

This impressive product is powered by 300hp Cummins QSL9 Tier 4 Final Engine, delivering the highest-rated horsepower of any wheeled feller buncher on the market today. With a dedicated attachment pump and Quadco 24CP felling head, the 830B gets the job done faster.

Every Barko product prioritizes operator safety without sacrificing performance capabilities. Simple ergonomic controls, a large touchscreen display, polycarbonate windows, A/C and a comfortable seat with ample legroom and storage space make it easy to tackle tough jobs. Rearview and skylight cameras with in-cab display come standard to enhance visibility while operating the machine.

Barko has over 55 years of experience developing and building high-quality, innovative forestry equipment. From harvesting to loading and land clearing to log hauling, Barko builds every piece of equipment with rugged components that are suitable for the most demanding jobs in the industry. Barko’s dealer network encompasses North and South America, Europe and Australia.

Since 1963, Barko has focused on cultivating a vast network of experienced distributors who are proud to recommend Barko products for the most demanding jobs in the forestry industry. For Barko, doing business is about much more than sales – it’s about providing the right machine for the job and innovating to deliver new features and capabilities that help operators get more done.

The Barko team will be attending the 2019 Mid-Atlantic Logging & Biomass Expo, Friday-Saturday, May 3-4, 2019 in Laurinburg, North Carolina. Barko invites trade show attendees to stop by the Barko/John Woodie Enterprises booth to learn more about the most innovative machines in the forestry industry and witness a live demo of the new 830B Wheeled Feller Buncher in action.

About Barko Hydraulics

Barko Hydraulics, LLC (Barko) is part of the Pettibone, LLC Heavy Equipment Group. Barko is a developer, manufacturer and distributor of innovative heavy equipment solutions for the forestry, site prep and material handling markets. Tough, dependable and powerful since 1963, Barko’s forestry innovations have become the standard for equipment designs and are the machines of choice among customers. Barko is headquartered in Superior, Wisconsin and is committed to delivering exceptional productivity at a lower total cost of ownership. Barko’s line of forestry equipment includes tracked harvesters, processors, loaders, Strong-Arm grapples, industrial wheeled tractors and more. For more information, visit Barko.com.

Aiken, SC – Hutto Wood Products has added another great option in their line of shaving mills, their new Block Shaver. This compact mill is designed to focus on cut-offs, loose ends, and other scrap wood material ranging from ½” up to 6” of scraps or round wood, regardless of species. Like all of Hutto’s mills, the new Block Shaver is built to last, hands free, 100% ready to run when it arrives and most importantly – affordable! If you are tired of seeing blocks and other scrap material pile up – the new Block Shaver is for you!

Hutto Wood Products has many shavings mills in their lineup, including a block shaver that was built over 5 years ago. With vast improvements on the new mill, the comparisons to it or other waste shavers aren’t close. Expanding the size of scrap sizes the machine can handle will allow mills to turn virtually any size cut-offs they have into profits!

Hutto Wood Products has focused on building high-quality, affordable shavings mills ranging from 3 to 60+ yards per hour. To find out more about the new Block Shaver, visit www.HWPshavers.com or call 803-564-7173 today!

.gif)