Woodworking Equipment For Sale

2046 Results Found

$ 99,900

VIET OPERA 7-5.3 HRKXF 1,350 mm (53.15") 5-Head Knife Planer/Calibrating Sander, with 3,634 Powered-On & 675 Run Hrs.Specifications: -- Thickness cap. 200 mm (7.87";).Equipped with: -- 1st Head: “HPG"; Planer Unit, with 180 mm (7.09";) Dia. Cutterhead with (520) Knives & 30 kW (40 HP) Motor, 26-Section Front pressure shoe, & Single back pressure shoe with chromium anti-wear lip. -- 2nd Head: “2620"; Working Unit, with 320 mm (12.60";) Dia. 90 Shore Rubber-covered contact roll with 22 kW (30 HP) Motor, Camshaft system belt cleaning blower, & Single front pressure shoe with chromium anti-wear lip. -- 3rd Head: “KOMBI 2620"; Combination Working Unit, with 190 mm (7.48";) Dia. 60 Shore Rubber-covered contact roll, Platen with “IPA"; Electronic segmented pad with (42) Segments, 32 mm (1.26";) Pitch, Low-pressure action, & Contact insert with Steel & felt grooves & Removable graphite cloth, 18.5 kW (25 HP) Motor with Electronic inverter, & Camshaft system belt cleaning blower. -- 4th Head: “X-SPIN PLUS"; Unit, with (15) Discs, with Steel inserts & Slots for 180 grit abrasive inserts, & 11 kW (15 HP) Motor with Electronic inverter. -- 5th Head: “2620"; Superfinishing Unit, with 2,160 x 1,420 mm (85.04"; x 55.91";) Chevron belt with Removable graphite cloth, & Platen with “IPA"; Electronic segmented pad with (42) Segments, 32 mm (1.26";) Pitch, Low-pressure action, & Contact insert with Steel & felt grooves & Removable graphite cloth, 15 kW (20 HP) Motor with Electronic inverter, & Camshaft system belt cleaning blower. -- All heads with Disc brakes. -- Adjustable 55 Shore spiral grooved rubber-coated pressure rollers. -- 200 mm (7.87";) Dia. “SCOTCH-BRITE"; Brush roll, with 1.1 kW (1-1/2 HP) Motor. -- Rotary Panel cleaner, with Air saving system. -- 50 Shore Rubber ground laminar surface vacuum feed belt, with 900 mm (35.43";) Height, 7.5 kW (10 HP) Motor with Electronic inverter, & Pneumatic belt tracking. -- 3-Roll Front & rear table extensions, Each with (1) Driven & (2) Idler Rollers. -- All motors with IP54 & Thermal relay protections. -- Self-lubrication system for pneumatic components. -- Front safety bar. -- Carbon steel electro-welded profile frame. -- IPC 15"; Touchscreen control (“SOPHIA"; IoT Connection-ready), with 100-Working program memory, Motor load meters, & Electronic digital readout with Automatic thickness positioning.Complete with: -- Translucent “LEXAN"; Side doors. -- 150 mm (5.91";) Wireless Panel Thickness Caliper.

$ 105,840

Viet Opera 5-4.3 RRRR, (4) Head Wide Belt SanderCalibrating Sander (89 Hours)53″ wide cap. - Drum, Drum, Drum, DrumHead Configuration1st Head: 9″ Helical grooved steel drum powered by a 22 kW or 29.5 HP motor.2nd Head: VARIABLE SPEED (via VFD) 9″ helical grooved rubber drum powered by a 18.5 kW or 25 HP motor. 3rd Head: VARIABLE SPEED (via VFD) 11″ helical grooved rubber drum powered by a 15 kW or 20 HP motor. 4th Head: VARIABLE SPEED (via VFD) 11″ helical grooved rubber drum powered by a 15 kW or 20 HP motor.5th Station: Dust brush powered by a 1.27 kW or 1.7 HP motorSpecifications -- The durometer does get softer from head 2 to 3 and then from head 3 to 4. -- It has 53″ width capacity and a 200 mm or 7.87″ thickness capacity. -- Right above the machine's infeed, you will find inspection LED lighting, a digital thickness calibration unit, and a wireless Mitutoyo Digimatic Caliper that communicates with the Opera’s operating system. -- The vacuum bed is powered by an 11 kW or 15 HP blower under the sander to save space. -- The feed mat is powered by a 5.5 kW or 7.5 HP motor with variable speed via a VFD with feed speeds from 9.8 to 52.4 FPM.Equipped with & Features -- Inside you will find interior LED lighting while all the controls on this Opera are upfront via a touch screen -- Constant pass lineNOTE : This calibrating sander has a total of 1,982 power on hours and ONLY 89 run (conveyor) hours. This is a very loaded, LOW Viet Viet Opera 5 (4) Head 53″ Calibrating Sander

Call for Price

VIET Planer Sander Sander model S2 321 HR/KRT ( 2018 ) !st head planer with helical insert cutter knives 30 HP 460 volts 2nd head drum contact roller 3rd head combination drum rollers with finish platen Both sanding heads run by 30 HP motor 460 volts Adjustable rubber coated pressure rollers Opening capacity range 1/8” to 6” Sanding belt size 44” x 103” Feed speed 19 to 52 FPM Electronic digital readout with auto thickness positioning Disc brakes on each machining station Front and rear emergency push buttons Electro pneumatic sanding belt tracking This machine has low hours as owner only ran half days first year and less after next years

$ 28,300

VIET - S211 R+ KRT, 2-Head Wide Belt Sander43" Width. cap.: Drum and Combination head.Head Configuration:1st Head: 160 mm 6.3″ Helical grooved rubber drum. 25 HP motor2nd Head: 160 mm (6.3") Helical grooved rubber drum with a platen combination head., 25 HP motorSpecifications: -- Each heads are powered by a 25 HP motor. -- The heads can be programmed to pneumatically raise & lower along with the platen and do (3) sanding combinations (with the twist of a button). -- Digital height readout and a calibration unit to the left side of the conveyor. -- Conveyor speed is controlled via a variable frequency drive 2.5 HP . -- Max width: 43″. -- Max. height: 6-1/4". -- Variable speed conveyor belt drive from: 3 - 16 MPM (11 - 52 FPM).Equipped with & Features: -- Both heads are equipped with: 1,130 x 1900 mm (44-1/2" x 75"). -- Roller & pressure shoe holddowns. -- Pneumatic tension of sanding belts and feed conveyor. -- Load meter on main motor. -- Disc brake on main motor. -- Emergency stops front & back. -- Roller table extensions front & back.NOTE: This is an extremely low-hour 2012 BIESSE Viet S1 dual head 43″ calibrating Wide Belt Sander.

$ 1,500

For pre-glued PVC, veneer, & melamine laminate coil stock; 0.4 - 1.2 mm edge thickness; up to 35 mm panel thickness cap., automatic coil feed. -- Equipped with: Electronically controlled temperature setting for hot air blower; 3,000 Watts for up to 650° F temperature; (1) Min heat up time. -- Guillotine type front & rear end trim (with fast speed, flying knife); top & bottom flush trims with single motor drive to cutterheads. -- Overhead belt type feeder; 16 FPM feed speed. -- Mounted on machine base with panel support table.

Call for Price

Vitap Forma Boring Machine 21 Vertical Spindles 21 Horizontal Spindles Approx $1000 worth of carbide bits DUAL LINE machine and there are (2) vertical lines of 21 spindles each for a total of 42 ...... PLUS an additional single line of 21 horizontal spindles!

Call for Price

VITAP POINT K2 2.0 CNC MACHINING CENTER (W/ATC/BORING) + Includes "VITAP Bar Nesting System." -- Specifications: VITAP - K2 2.0 CNC Center is the best and most technically advanced machine for wood processing. The K2 has a patented "Double Dynamic Transport (DDT)" System with a double clamp technology that creates smooth panel movement.With an automatic tool changer and modern software, the programming for this machine is easy and efficient to use. This machine is perfect for companies of all sizes and is the optimal choice for your CNC woodworking needs. -- Working Field:Max. panel size "X" Axis infinite; "Y" axis 49.2" (1,250 mm); "Z" axis 1.97" (50 mm).Min. panel size "X" axis 10" (270 mm); "Y" axis 5.9" (150 mm); "Z" axis 0.1" (3 mm). -- Positioning Speed:"U" Axis Panel feeding speed 82 FPM (25 MPM); "X" & "Y" axes 197 FPM (60 MPM); "Z" axis 49 FPM (16 MPM).Axes positioning by AC drives & brushless motors; the "Panel" moves in "X" axis & the "Machining Units" move in "Y & Z" axis.Max. Panel weight is 176 Lbs (80 kG). -- Work Area: Vitap "DDT" + "Vitap Bar Nesting System":DDT is short for "Double Dynamic Transport", a clamping system for work pieces on CNC Machining Centers, for moving the workpiece in "X" axis.The function of the DDT system consists of: (2) Gripper/clamps that move the workpiece in the same or alternate direction. This allows for a significantly longer travel distance of the workpiece compared to the travel distance of the gripper/clamps. DDT system is a requirement for Bar Nesting."VITAP Bar Nesting" is a special form of combining a Beam Saw & Nesting at the same CNC Machining Center. VITAP Bar Nesting is also designed to combine the advantages of nesting technology with the possibility of horizontal drilling.VITAP Bar Nesting is a technology that has been specially developed for VITAP Machining Centers. The prerequisite is a machine in which the X-axis is generated through the movement of the work pieces. A further prerequisite is the presence of (2) grippers for workpiece movement, known at VITAP as "DDT-System".Bar Nesting is not a complete nesting of the work pieces, as the large-sized (Ripped) panels must still be cross-cut into stripes on a Saw.NC Controlled "Optical Material Sensor" creates a “0“ Panel reference point by reading the panel's ends; this ensures that RH & LH (mirror image) panels will always be symmetrical.Fixed RH ("U" axis) panel clamping device with: Automatic panel adjustment according to the programmed information; LH side pressure clamp with automatic adjustment & pneumatic locking according to the panel width; scratch resistant idle rollers for panel positioning from the bottom & sides. -- Boring Unit: (1) 2.2 HP (1.7 kW) - 3,600 RPM motor; (12) independent vertical spindles on 32 mm centers with 6-spindles in "X" axis & 6-spindles in "Y" axis.(8) Horizontal Spindles with: (2 + 2) spindles in "X" axis & (2 + 2) spindles in "Y" axis.(1) "X" Axis grooving saw: 7,000 RPM with 100 mm

$ 41,500

VITAP BLITZ CNC BORE, GLUE & DOWEL INSERTER: -- Specifications:(1) CNC Controlled head assembly with rapid (side-to-side) traverse, assembly with boring, gluing & insertion unit, This Flexible machine is IDEAL for JIT or high production runs. -- Working Area:Useable working area "X" axis 36.2" (920 mm), "Y" axis 3.14" (80 mm), "Z" axis up to 1.57" (40 mm) material thickness with digital readouts -- BG & D Unit(1) 1 HP - 6,000 RPM horizontal drill motor; 0.47" (12 mm) Maximum drill bit dia. (1) Glue injector & (1) dowel Inserter with 1.57" (40 mm) Max. dowel lengthMachine is capable of processing dowel diameters from 6 mm dia x 25 mm long - 10 mm dia x 40 mm long dowels (currently setup for 8 mm dia dowels); -- Operator & Machine Control:CNC "Color Touch-Screen" Controller for function & simple part programming and program storage. -- Complete with: (1) 12" Dia. vibratory feed hopper, totally sealed electronically metered glue system with "Automatic" injector flushing; (1) 4.75 G (18 L) Glue tank & (1) 2.37 G (9 L) water tank;(4) Inclined vertical pneumatic hold-down clamps; Function selector control for boring only or doweling; Anti-slip table surface, Rack & pinion drive and centralized dust collection manifold.

VITAP ALFA - 27: Construction/Line Borer27-Spindle boring head on 32 mm centers; drills vertically from bottom-up and head rotates to horizontal position for edge boring; head rotation is pneumatic with switch control. -- 2-3/4" Max. drilling depth; 2-1/2 HP - 2,800 RPM motor; pneumatic drill head advance with speed control; head height adjustment with mechanical digital readout; 34" x 20" table size; max. workpiece width 31-1/2". -- Equipped with: Left- & right-side fences for construction boring; (2) pneumatic holddown clamps; 118" line boring fence w/flip stops; pneumatic foot pedal control; magnetic starter; overload protection.

$ 4,500

VITAP RC 92 Semi-Automatic Top & Bottom Edge Trimmer, New, Never Used!Specifications: -- For straight & curved edge banded panels. -- Max. edge thickness 3 mm (0.12"). -- Panel thickness 10 - 60 mm (0.39" - 2.36"). -- Table size 27" x 31".Equipped with: -- (2) 0.55 kW (0.7 HP) - 12,000 RPM Spindle motors. -- Large dia. guide bearings to ensure precise trimming of edges.NOTE: Sold "As Is" without Warranty!

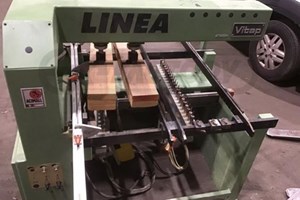

VITAP LINEA 42 Line Boring SystemSpecifications: -- (2) Drill heads of (21) spindles ea., drills from bottom up, ea. support with 2 HP motor and (21) spindle boring block w/panel support mounted on top; -- Drills panels from 100 - 3,000 mm in length, and 100 - 950 mm in width. Complete with: -- Digital readouts for boring blocks, 2,000 mm bar scale fence with (5) adjustable flip stops. -- (2) Moveable overhead pneumatic holddown cylinders, foot pedal for clamping & boring cycle.

Call for Price

Call for Price

The VOLPATO LS-1N 1A Wide Belt Sander, introduced in 2006, epitomizes precision and efficiency in the woodworking industry. Crafted with advanced technology, this machine excels in delivering impeccable sanding results on wood surfaces, showcasing its commitment to high-quality finishing. Designed with a robust and reliable structure, the LS-1N 1A ensures stability during sanding operations, contributing to the production of top-notch wood products. The wide belt configuration allows for efficient material removal, achieving smooth and consistent finishes across various wood types.

$ 46,900

VALPATO LBK-150-ST 1 Feed Through Profile SanderTECHNICAL FEATURES: An added small needle type drum sander can be fitted with drum sanding aggregates of 25, ­30, ­35,­40, ­45 ­50 mm diameters which can be used for tighter curves and smaller radius sanding requirements. Storage compartments (2 in total) are located on each machine extremities, these are easily accessible and can be used for sanding belts and various tooling storage. Sanding belt motor power: 3 Kw Abrasive head motor power: 1.5 Kw Oscillation motor power: 0.38 Kw Feed motor power: 0.75 Kw Motor power for electrical adjustment of sanding group: 0.19 Kw Machine voltage: 480/3/60 Full Load Amps @ 480V: 15A Compressed air: Not required Dust collection requirement one (1) only 6" (150mm) port: 950 CFM Sanding belt speed: 14 Mt/sec Variable speed of the belt: from 5 to 25 m/min Sanding belt dimensions: 150 x 2640 mm Height of working table: 930 mm Dimensions of front working table: 1980 x 250 mm Machine dimensions: 2500 x 900 x 1600 mm Net weight: 1000 KMAIN FEATURES: User friendly PLC touch screen control panel is accessible from 360° by the operator, the control panel is centrally located on the infeed end of the machine. Factory installed variable feed drive (VFD), enables machine to run from 5 M/Min to 25M/min (+/­ 80 ft/Min). The entire sanding plenum rise and fall is motorized, it can be adjusted vertically in height to utilise the full height/width of the sanding belt. An oiling unit ensure long life of sanding plenum rise and fall master cylinder.

$ 16,750

VOORWOOD "A 515 GH" Arch Door Sander with Floating Head ARCH SANDER with: (4) 1.5 HP Motors for precision sanding; quality sanding using Disc sanding at continuous feed. Equipped with: -- (4) Floating Sanding Stations equipped with: 1.5 HP Precision balanced drive motors and quick change spindles. -- Infeed & outfeed (1st and last) spindles equipped with: Double collets and angular, horizontal & vertical adjustments with accurate and repeatable digital readouts. -- PLC Control with: Monitor at eye level height.Feedthrough Arch Machine capable of sanding arch profiles on cabinet door components, plus can do straight cuts.. .

$ 49,500

VOORWOOD M 15A CNC Round End Tenoner & Mortiser for 45° Door --The "M15A" Miter Machine is designed to rapidly make mortise and tenon cuts at 0°, 45° Only, . Parts can be up to 1.5"; thick and up to 4"; wide, and of ANY length. --A primary application for this machine is for miter cabinet door frames. Parts can be quickly transferred from left to right. They are mortised on the left side of the machine and tenoned on the right. The machine can also mill the slots. --Specifications & Equipped with: -- The mortise station has (3) servo-controlled axes (X, Y, and Z) that are coordinated by the machine controller to achieve complex CNC motion. It is equipped with a collet-style router spindle for cutting. The tenon station uses the same X- and Y-servo-controlled axes as the mortise station and is configured for pneumatically actuated in-and-out movement along the Z-axis. The tenon station is equipped with a direct drive shaper spindle for cutting. -- -- Pneumatic clamping assemblies with non-marring urethane pads are mounted to the hold-down assembly to secure the parts during cutting and these can be adjusted to various locations over the cutting surface. -- -- M15 Miter Machine operator interface consists of a colored touch screen. For simplicity, the entire calibration, setup, and monitoring of the machine are accomplished using only four touchscreen displays. The program designs the depth and location of both the mortise and the tenon. When the design is complete, it is saved in a recipe format. Once this recipe is opened, the operation is as simple and boils down to feeding the substrate into the machine. -- -- The full-color touchscreen panel is located on the front of the machine to provide easy access for setting up or operating the machine. Clamping and shaping operations are controlled by operating lighted pushbutton switches.

Call for Price

This item is in an Auction on exfactoryauctions.com. Go here to view item: http://exf.ac/i6h WADKIN JET-3 Single End Tenoner/End Jointer Specifications: For Windows, doors, finger jointing, & stair strings. Stock type: PAR & Moulded. Max. tenon length 120 mm (4.72"). Max. stock width 150 mm (5.91"), Max. stock length: Unlimited, Max. stock thickness: 150 mm (5.91") for Rear tables, 280 mm (11.02") for Front table, & 450 mm (17.72") for Multiple tables. Vertical table adjustment 230 mm (9.06"), Horizontal table adjustment 25 mm (0.98"). Cutterhead dia. 250 - 322 mm (9.84" - 12.68"). Cutterhead speed 3,600 RPM. Max. cutting speed 4 MPM (13 FPM), Return speed 8 MPM (26 FPM). Equipped with: (3) 7” x 27-1/2” Multi-level tables, Each with Adjustable height, Fence, & (2) with 3” Dia. Pneumatic hold-downs, Allowing machining of (3) separate pairs of parts in (1) pass or All joints of window frame/sash in (2) passes. (1) Trim/hog saw & (1) 50 mm (1.97") Dia. x 240 mm (9.45") L Stackable spindle with 7.5 kW (10 HP) - 3,420 RPM Motor, with Automatic brake.

Call for Price

WADKIN "GD 220" 5-Head Molder8-5/8" X 4-3/4" cap. - Head sequence: Bottom 7.5 HP, right 7.5 HP, left 7.5 HP, top 10 HP, bottom 7.5 HP motor.Other Specifications: -- All spindles 40 mm dia. at 6,000 RPM, with vertical and horizontal adjustments; electric spindle braking; (2) digital position indicators with tool radius compensation fitted to the horizontal movement of the right side head and vertical movement of the top head. 0.5 HP Motorized feed beam with pneumatic feed hold-down wheels; -- Cardan drive variable feed speed 18 - 72 FPM, 3 HP feed drive, reverse feed, 5-1/2" dia. hardened and chromed steel feed rollers up to top head, polyurethane feed rollers 2" x 2" after top head; all feed and pressure rollers move with the rise and fall of the feed beam. -- Diameter of cutting circle: minimum 100 mm all heads; for planing, maximum 125 mm all heads; and, maximum of 195 mm all heads for moulding. -- Complete with: Manual bed lubrication, 2-meter (78") infeed straightening table, sound enclosure and owner's manual.Like New Condition - this Moulder has never been used, and is still sitting on factory shipping pallet.

$ 17,900

WADKIN "GA-220" 5-Head Feed Through MoulderSpecifications: -- 5-Head, with 8-5/8" x 4-5/8" cutting capacity (220 mm x 120 mm) -- 40 mm Spindle diameter with cutterhead speed of 6,000 RPM. -- Head sequence: Bottom 10 HP, Right 7-1/2 HP, Left 7-1/2 HP, Top 15 HP, Bottom 10 HP motor. -- 2 HP variable feed speed 19 to 72 FPM, chain drive. -- Currently wired for 460 Volt, 3-Phase power.

Call for Price

WADKIN GD 220 6-Head Feed Through MoulderSpecifications: -- Working capacity: 230 mm W x 130mm H (9.06" W x 5.12" H) Timber admitted, 220 mm W x 120 mm H (8.66" W x 4.72" H) Finished timber. -- Head Sequence: Bottom 7-1/2 HP, Right 7-1/2 HP, Left 7-1/2 HP, Top 15 HP, Bottom 10 HP, & Universal 7-1/2 HP. -- Spindle dia. 40 mm (1.57"), Spindle speed 6,000 RPM. -- Variable feed speeds 6 - 22 MPM (20 - 72 FPM).Equipped with: -- Right, Left & Top heads with Mechanical digital readouts. -- 1/2 HP Motorized feed beam, 2.2 kW Feed motor, 3 HP Cardan drive, Reverse feed, 5-1/2" Dia. Hardened & Chromed steel feed rollers up to top head, 2" x 2" Polyurethane feed rollers after top head, All feed & pressure rollers move with rise & fall of feed beam. -- 2 M (78.74") L Infeed straightening table. -- Manual bed lubrication. -- Sound enclosure.

.gif)