704-841-2001

Backed with a massive machinery database considered to be “the blue book” of woodworking machinery), EX-FACTORY Auctions provides a complete assessment of your equipment and allows you to interact with the market real-time in our dynamic Online Auction!

1823 Results Found

704-841-2001

LHI POWER RIPPER Straight Line "Rip Saw":Will perform 80% of the jobs done by other Straight-line Rips costing up to four times as much.Specifications: -- 10 HP arbor motor - 230V 1-Phase or 220/440V 3-Phase -- 1 HP feed motor and integral feed unit. -- Variable speed drive or 50 to 180 FPM; fixed feed speeds available (150 FPM standard). -- Cogged steel drive wheels, optional non-marking Polyurethane wheels. -- Easy to change 12" dia. blade - just drop the arbor frame, loosen the arbor nut and change blade. -- Fully enclosed blade plus heavy-duty kickback fingers and heavy gauge belt and chain guards. -- Easy-adjust fence with hand crank and positive lock clamps. -- 4' x 5' Table size with right or left-hand fence available.Options & Features: -- Can be set up to rip hardwoods or softwoods up to 2.75" thick and 3/4" plywood or particleboard up to 4' x 8' in size. -- Available with Quick-Set Fence and digital readouts for lightning-fast size changes.Digital readout, add $2,495

Call for Price

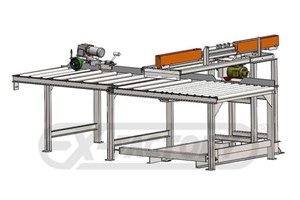

LHI MODEL RFPR AUTOMATED PANEL RIP SYSTEM --Arranged for up to 5/8"; Thick x 52"; Wide x 18’ Long Panels as follows: AUTOIMATIC INFEED SYSTEM, INCLUDES: --Rake Feeder for up to 18’ Long Sheets --Automated Feed Cycle Controls --Turnkey Controls, Plug it in and Run --1 HP, 3-Phase, 460-Volt Operation 6’ ALIGNMENT CONVEYOR, INCLUDES: --Gravity Roller Frame with 60"; Wide Rollers --Alignment Fence --Spring Loaded “Feather"; to Keep Sheets Tight to the Alignment Fence --Powered Feed Wheel to Push Sheets into the Ripsaw --2 HP, 3-Phase, 460-Volt Operation TANDEM INFEED SCISSORS LIFT --8,000 LBS. Capacity --30"; x 204"; Platform With 62"; Rails Mounted Across the Lift for Fork Lift Entry. Rails are Evenly Spaced Down the Length of the Lift --62"; x 204"; Useable Deck Size. --Automatically Raised and Lowered by Signals from the Sheet Feeder --2 HP, 3-Phase, 460-Volt Operation TANDEM OUTFEED SCISSORS LIFT --8,000 LBS. Capacity --30"; x 204"; Platform With 62"; Long Rails Mounted Across the Lift for Fork Lift Entry. Rails are Evenly Spaced Down the Length of the Lift --62"; x 204"; Useable Deck Size. --Automatically Lowers by Signals from Auto-Down Index Control Unit --2 HP, 3-Phase, 460-Volt Operation --OPTIONAL: 4-Sided “Accordion Skirts"; for each Tandem Lift Table, add $2.650 per lift RFPR" ROLL FEED PANEL GANG RIP SAW --50 HP Main Arbor Motor --1/8" Min. To 1-1/4" Max. Material Thickness x 72" Cutting Width --10" Dia Blade Design; 3-15/16" Dia. Arbor with 72" of Usable Width Cutting Capacity --Min. Panel Length 30". --1-15/16" FAFNIR Arbor Bearings --(8) Polyurethane Feed Rollers on 6" Centers --Variable Feed Speeds Via VFD --(1) Quick Blade Change-Out Kit --(1) Additional Arbor Cart --(2) 4" Dia. Dust Collection Ports on Top and (1) 8" Dust Collection Port on Bottom. Total Recommended 1,500 CFM. TOOLING: --(20) Saw Collars, Mount Directly to the Arbor with a Set Screw --(20) Saw Blades Configured for Clean Cuts on Your Panels

LHI RFPR-72/16 "HEAVY DUTY" MULTI-BLADE PANEL RIP SAW (W/LOADING/UNLOADING): -- Specifications (1) 30 HP Main arbor motor for 1" min. - 5" max. material thickness;16" Dia max. blade capacity with 1.25" minimum spacing between the blades;Minimum panel length 30" with 72" of usable width cutting capacity.3-15/16" Dia. arbor with 1-15/16" precision arbor bearings;Positive powered steel contact feed rollers with (8) adjustable Polyurethane drive rollers;Variable feed speed to max 80 FPM.Available Options Include:Single point height adjustment for materials from 1" to 5" thickness using customer supplied 16" dia blades(note: Ripping widths can never be less than one-half the material thickness).(1) "Quick Change" arbor cart trolley and blade box for QC set ups.(12) Saw collars to attach the customer supplied 16" dia. diamond blades to the arbors(1) In-feed Scissors Lift with auto cycle controls(1) In-feed 6' conveyor with alignment fence and powered assist feed(1) Auto sheet feeder with auto cycle controls(1) Out-feed Scissors Lift with 4 x 8 roller top.Installation technical assistance for $125/Hr plus travel time and expenses, payable upon competition of services. NOTE:Quote is valid for 30-days;Quoted price is FOB, Factory;Customer is responsible for off-rigging cost at their facility;Customer is responsible for spotting the machine to its final resting place with adequate floor foundationCustomer is responsible for adequate electric, air & dust control supply upon technician's request:Warranty: 1-yr mechanical parts (electrical controls excluded);Delivery to Customer's facility is approx 17 weeks from receipt of funds;Quote assumes customer will deliver material for testing & run-off procedures (if required);NOTE: PRICING DOES NOT REFLECT FACTORY'S 10% MATERIALS SURCHARGE

LHI RFPR 72/12 "HEAVY DUTY" MULTI-BLADE PANEL SAWSpecifications -- (1) 50 HP main arbor motor for 1/8" min. - 2" max. material thickness; 12" Dia max. blade capacity with 1.25" minimum spacing between the blades; Minimum panel length 30" & 72" of usable width cutting capacity. -- 3-15/16" Dia. arbor with 1-15/16" precision arbor bearings; positive powered steel contact feed rollers with (8) Polyurethane drive rollers; variable feed speed to max 80 FPM. -- (1) "Quick Change" arbor cart trolley and blade box for 9 1/2" cutsOn average this machine will cut a bundle (42 sheets) of 3/4" Plywood. LVL, PB, MDF or OSB into narrow strips in 4 minutes or less.Available Options: -- Blade Box Arbor Cart and Trolley $ 12,590.00 each -- Arbor Carts modifications to accept 12" dia. blades $ 700.00 each -- Single Point Height Adjustment $ 6,000.00 each -- "Quick Change" set up kit (includes belt guide, belt tensioner, and hydraulic arbor lock) $ 3,695.00 each -- Tandem 8000# capacity infeed Scissors Lift, 2 HP, 3 Phase, 230/460 Volt, 31" x 192" platform and cross bars for fork truck entry $ 14,495.00 each -- Tandem 8000# capacity outfeed Scissors Lift, 2 HP, 3 Phase, 230/460 Volt with 48" x 192" platform and beveled crossbars for fork truck entry and auto down indexing $ 16,390.00 eachTooling Cost: -- Carbide Tip Blades 12" x 40T x 4 3/16 bore with TCG and 3 pin holes $ 125.00 each -- Saw Blade Tooling Collars $ 125.00 each -- Actual Model is LAUDERDALE-HAMILTON RFPR "HEAVY DUTY" 12 Panel Rip SawNOTE: PRICING DOES NOT REFLECT FACTORY'S 7% MATERIALS SURCHARGE

$239,800

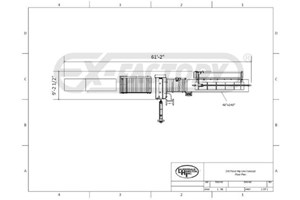

LHI 96" x 60" ANGULAR TYPE RIP & CROSS-CUT SYSTEM: Specifications: -- Automatic Angular Rip & Crosscut 5-Position System; max. panel size of 8' (96") long x 5' (60") wide x 1" - 4" thick; 1.25" minimum spacing between the blades; variable feed speed from 0 - 150 FPM. This system will process a unit of material in approx. (7) Min. -- Pos. # 1: LHI Automatic Staging/Infeed/Transfer & Panel Rake Feeding System: 10' (120") Long, powered 3-chain staging conveyor; (2) units can be preloaded while (1) unit is in process. Automatic up-indexing 4,500 Lbs capacity Scissors Lift with auto. rake infeed system: infeed rake system designed with a thin material device that can automatically load material as thin a 1/8". -- Pos. # 2: LHI "72": 72" Arbor length designed for panels up to max. of 5' (60") wide, min. panel length 30"; 40 HP main arbor motor; 1/8" min. - 1" max. material thickness with no adjustment needed over a 3/8" thickness variation. 2-3/4" Dia. arbor with 1-15/16" "Fafnir" arbor bearings; positive non-marking steel contact feed rollers with (optional) poly-covering, driven from top & bottom. Includes: (6) blade collars; (2) 6" dia. vertical dust outlets with an easy access strip separator box. -- Pos. # 3: LHI Cross-Transfer System: Transfer conveyor with panel hold-down & chain drive system to change direction 90° & automatically feed LHI 102". -- Pos. # 4: LHI "102": 102" Arbor length designed for panels up to max. 8' (96") long; 30 HP main arbor motor; 1/8" min. - 1" max. material thickness with no adjustment needed over a 3/8" thickness variation; 2-3/4" dia. arbor with 1-15/16" "Fafnir" arbor bearings. Positive non-marking steel contact feed rollers with (optional) poly-covering, driven from top & bottom. Includes: (6) blade collars; (2) 6" dia vertical dust outlets with an easy access strip separator box. -- Pos. # 5: LHI Stacking & Outfeed Transfer System: Auto. down-indexing 4,500 Lbs cap. Scissor Lift; (4) adjustable alignment posts & (4) bin separators to keep processed stacks square. 98' (96") Long outfeed gravity conveyor.Operating System: -- (1) LHI ALLEN-BRADLEY "Inter-Link" PLC for simple single-operator management of the entire system from (1) central control.NOTE: ...Attached description & pictures are for INFO purposes only; ...a NEW System can be modified to your exact specifications!NOTE: PRICING DOES NOT REFLECT FACTORY'S 10% MATERIALS SURCHARGE

$43,600

LHI RFPR-72/10 MULTI-BLADE PANEL SAW: Specifications: -- 40 HP main arbor motor; 1/8" min. - 1-1/4" max. material thickness; 10" dia blade with 1.25" minimum spacing between the blades; -- 3-15/16" Dia. arbor with 72" of usable width cutting capacity, min. panel length 30"; -- 1-15/16" precision arbor bearings; positive powered steel contact feed rollers; -- Fixed feed speed of 80 FPM. Blades & collars: -- Thin kerf 10" dia x 40-tooth x 4.18" bore non-split blades with quick & easy setup for fast blade positioning/removal (blades not included). -- Blades & collars are sold separately & not included in the machine price; 10" dia. x 40-tooth thin kerf blades, please add ...$ 105 ea.;1.25" wide x 4.18" bore blade collars, add ...$ 145 each. Complete with: -- (2) 4" dia dust collection ports on top and (1) 8" dust collection port on bottom. Total recommended 2,200 CFM -- Actual Model is LHI RFPR-72/10 Roll Feed Panel Saw. Available Options at additional cost: -- 110 V Infeed Scissor Lift with foot pedal controls or automatic up-indexing; 110 V Outfeed Scissor Lift with automatic down-indexing;Assortment of blade thicknesses & diameters; Split blade & collar system; Additional Options Depending on application: -- Main motor power from 30 - 75 HP; 4" Max. cutting height (requires 75 HP motor); -- Variable feed speed; Non-marking Polyurethane contact feed rollers; -- Additional arbors; "QUICK CHANGE" arbor system (see video); -- "Pigtail" quick change Crosscut Saw System.Many more tooling & configuration options available upon requestThis machine will cut a bundle (42 sheets) of 3/4" Plywood. PB, MDF or OSB into narrow strips in (4) minutes or less.NOTE: PRICING DOES NOT REFLECT FACTORY'S 7% MATERIALS SURCHARGE

$54,780

LHI RFPR 102/10 MULTI-BLADE PANEL SAW: with 102" of usable width cutting capacity. Specifications: -- (1) 40 HP main arbor motor for 1/8" min. - 4-1/4" max. material thickness; min. panel length 30"; 102" of usable width cutting capacity. -- 12" Dia max. blade capacity; 1.25" minimum spacing between the blades; -- 3-15/16" Dia. arbor with 1-15/16" precision arbor bearings; -- Positive powered steel contact feed rollers with (8) Polyurethane drive rollers; fixed feed speed of 80 FPM. -- Includes (6) arbor collars - blades not included. -- Complete with:(2) 4" dia dust collection ports on top and (1) 8" dust collection port on bottom. Total recommended 2,200 CFM.Available Options: -- Blade Box & "Quick Change" Arbor Cart and Trolley $12,590.00 each -- Arbor Carts modifications to accept 12" dia. blades $700.00 each -- Single Point Height Adjustment $ 6,000.00 each -- "Quick Change" set up kit (includes belt guide, belt tensioner, and hydraulic arbor lock) $3,695.00 each -- Tandem 8000# capacity infeed Scissors Lift, 2 HP, 3 Phase, 230/460 Volt, 31" x 192" platform and cross bars for fork truck entry $14,495.00 each -- Tandem 8000# capacity outfeed Scissors Lift, 2 HP, 3 Phase, 230/460 Volt with 48" x 192" platform and beveled crossbars for fork truck entry and auto down indexing $16,390.00 each -- Drag Chain Feeder Conveyor - Roller conveyor transfers sheets to in-feed of saw and dog chains align and start the sheets into the saw feed rolls. Recommended with 102" wide machines, $18,800 Tooling Cost: -- Carbide Tip Blades 10" dia. x 40-tooth thin kerf blades $125.00 each -- Saw Blade Tooling Collars $125.00 eachOn average this machine will cut a bundle (42 sheets) of 3/4" Plywood. LVL, PB, MDF or OSB into narrow strips in 4 minutes or less.NOTE: PRICING DOES NOT REFLECT FACTORY'S 10% MATERIALS SURCHARGE

$52,733

LHI PIGTAIL Crosscut saw with conveyor and air stopSpecifications -- 62" Cut width --Saw motor 5 HP -- 14 FT gravity conveyor cutting surface -- Cam Lock adjustable stop -- Power feed wheel for rip saw infeed assist -- Blade dia. 12"Equipped with and Features -- 4,500 lb lift with loading ramps 1 HP, 30" X 72" platform -- 4,500 lb Outfeed lift with 3 ramps, 48" X 96" Platform, Auto down indexing -- 10" X 40T X 4-3/16" , 30 Blades -- 3-15/16" ID x 4.18" bore x 1.25" wide 30 collars -- 32 Throat Plates

$4,900

NASH 45-72 Spindle Sander(4) Spindles, 4" min to 72"max/. chucking cap., 3/8" - 6" dia. range;Specifications: -- 2-1/4" Dia. main arbor with long keys for driving head & tailstock wheels. -- Variable spindle speeds from 700 - 3,000 RPM, 7.5 HP spindle motor, 2 HP feed & oscillation rack motor, variable oscillating speed (60 - 120) strokes/Min, oscillating stroke adjustable up to 2" in length. -- (5) 72" Sanding racks, self-adjusting & oscillating. -- Equipped with: Overhead mounted dust hood (to be verified), push button control panel; production rate of (10 - 30) pieces/Min. -- Includes: brushes and sandpaper.

NEDERMAN - S-750: Bag House Dust Collector7.5 HP - 1,750 RPM TEFC Motor. -- (24) BEANE material filter bags; (3) plastic waste collection bags; (3) clamps for easy removal of waste bags. -- Features: 243 Sq/ft. of filter media; easy installation typically (1) hour; quiet operation; (3) waste discharge points; 280 mm inlet. -- Unit is very versatile and capable of a nice range of operation; 2,500 CFM @ 10"Wg; 3,500 CFM @ 8"Wg; 4,500 @ 6"Wg. -- Magnetic starter included for 230 V - 3 Ph.

NEDERMAN S-750 BAG FILTER Dust Collector. The NEDERMAN S-Series Baghouse Dust Collector is quick to install and easy to operate. With a 7.5 HP motor and a 4,500 CFM @ 6" WG it's the ideal solution for the small shop or single work-cell operation. -- Specifications: 7.5 HP - 1,750 RPM TEFC Motor, (24) Beane material filter bags and magnetic starter. -- Features: 243 Sq/ft of filter media, easy installation, typically (1) hour; quiet operation, (3) waste discharge points. Inlet opening 11". -- Available in 208/230 or 480 V, 60 Cy, 3 Ph. Must specify voltage at the time of orderAvailable options:42 Gallons Drum Discharge - Single Drum (3 REQUIRED)230 Gallon Dump Bin

NEDERMAN S-500 BAG HOUSE DUST COLLECTOR. -- Open Bag house designed for interior application; 5 HP TEFC material fan motor, 1,750 RPM; free standing 2,000 CFM open frame bag house, 162 sq. ft. of filter area via (16) beane material filter bags; 7.5" W.G. static pressure. -- Bottom discharge into (2) plastic waste collection bag. -- Includes: Side-mounted blower assembly with support legs; (2) quick disconnect clamps for the plastic bags. Starter motor with push buttons. Option:42 Gallons Drum Discharge, Single Drum (2 REQUIRED FOR COMPLETE S-500)

NEDERMAN S-1000 BAG FILTER Dust Collector. The NEDERMAN S-Series Baghouse Dust Collector is quick to install and easy to operate. It's the ideal solution for a smaller shop or single work-cell operation.Specifications: -- With a 10 HP motor and a 5,000 CFM @ 7" WG and 360 Sq/ft of filter media. -- 10 HP - 1,750 RPM TEFC Motor, (24) Beane material filter bags and magnetic starter. -- Features: Easy installation, typically (1) hour; quiet operation, (3) waste discharge points. Inlet opening 16". Available in 208/230/460 V, 60 Cy, 3 Ph. Must specify Voltage at time of orderAvailable option:- Aluminum Impeller: - 45 Gallon Drum Discharge - Single Drum (3 REQUIRED)- 230 Gallon Dump Bin: Available spare parts:- Filter Bag (24 Filters)- Plastic Bags (Roll of 90 - 8 mil thickness) - 500mm Clamp (bags, barrels, and bin)

NEDERMAN - S-1000: BAG FILTER Dust CollectorNEDERMAN S-Series Baghouse Dust Collector is: Quick to install and easy to operate; ideal solution for the small shop or single work cell operation. -- Includes: 10 HP Motor; CFM range from: 4,000 CFM @ 8" WG to 5,000 CFM @ 7" WG. -- Equipped with: 10 HP - 1,750 RPM TEFC Motor; (24) BEANE material filter bags; (3) plastic waste collection bags; (3) clamps for easy removal of waste bags; magnetic starter. -- Features: 360 Sq/ft. of filter media; easy installation - typically (1) hour; quiet operation. -- Inlet opening: 15". -- Includes: -- ALLEN-BRADLEY Magnetic Starter. -- 16" Flanged inlet adapter.

NEDERMAN S-1000 BAG FILTER Dust CollectorNEDERMAN S-Series Baghouse Dust Collector is: Quick to install and easy to operate; ideal solution for the small shop or single work cell operation. -- Includes: 10 HP Motor; CFM range from: 4,000 CFM @ 8" WG to 5,000 CFM @ 7" WG. -- Equipped with: 10 HP - 1,750 RPM TEFC Motor; (24) BEANE material filter bags; (3) plastic waste collection bags; (3) clamps for easy removal of waste bags; magnetic starter. -- Features: 360 Sq/ft. of filter media; easy installation - typically (1) hour; quiet operation. -- Inlet opening: 15". -- Includes: -- ALLEN-BRADLEY Magnetic Starter. -- 16" Flanged inlet adapter.

$18,000

Newman HP-688 Twin Bay Hydraulic Cold Press6-Sections (top platens) each 24" x 30" each, Center posts between third and fourth platens, creating two overall areas of 30" x 74". Specifications: -- Max. fixed opening 48" with 11" cylinder stroke, each platen section has (1) 10" bore with 5" dia. ram cylinder; -- Each platen is 15/16″ thick and it’s back structure is webbed every 5-1/2″ X 7-1/2″. -- Side-mounted self-contained hydraulic system w/tank, 10 HP continuous operating pressure compensating pump. -- Hand-Valves to Cycle Individual Platens with pressure gauges for each platen. -- Idle Pop-Up Bed Rollers in the bottom platen for easy loading and unloading.Over all the press is in excellent condition, is extremely heavily built, and is also a beautiful impressive press in person.

NEWMAN - SS-24, ...Wood Shaving Mill -- Motor: 100 HP. -- Feed Opening: Up to 5" thick x 14" wide. -- Cutterhead: 24" Dia. x 14" width. -- Knives: (16) Per row x (7) rows; total: (112) knives. -- Some extra knives included. -- Loaded onto your truck.

Call for Price

This item is in an Auction on exfactoryauctions.com. Go here to view item: http://exf.ac/i6r NEWMAN S-248 24" x 8" Single-Sided Planer Specifications: Planing thickness 1/16” - 8”. Min. stock length 13”, 4” Butted. Infeed & Outfeed table sizes 24" W x 16-3/4” L. Feed speeds 20 - 100 FPM. Equipped with: 4” Dia. 4-straight knife cutterhead. Segmented serrated upper with 2” W Spring-loaded segments & (3) Solid steel lower feed rollers. Chip breaker, with 2” W Reversible spring-loaded segments.

$15,850

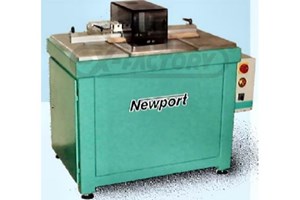

Specially designed haunching machine for beaded face frames, picture frames and decorative cabinetry. This machine uses a specially designed 2-piece carbide insert adjustable cutter. -- The work piece is placed on the table and against the fence and the cutter travels in a vertical motion to achieve the precision cut. -- Any size cut width is attainable by adjusting the width of the cutter and indexing from the fence stops. -- TECHNICAL SPECIFICATIONS -- Motors: 1 @ 1.1 KW (1.5 HP), Voltage: 220/440V/3/60hz, RPM: 6,000 RPM @ 60 hz, Air: 6 Bar, -- TOOLING: Insert Carbide: Milling head 140 mm (5.5"), Height min: no min., width 1/6" (4.2 mm). Max Profile: Height 3.5" (88.9 mm), width no max. -- Machine Dimensions: L x W x H - 40" x 30" x 35". Machine Weight: 675 lbs. -- AVAILABLE OPTIONS (Call for Pricing): Tooling carbide insert head, additional set of inserts, additional flip stops, foot pedal control, left & right digital fence.

Call for Price

//This machine is in an Auction on exfactoryauctions.com// //Link to machine: http://exf.ac/i59 NEWTON B-100 2-Spindle Air-Operated Horizontal Boring Machine Specifications: Table size 10” x 16”. Distance between spindle centers 1-5/32" - 7-1/4”. Max. boring depth 5". Max. clamping thickness 3". Horizontal table travel 5", Vertical table adjustment 3-1/2". Max. bit dia. 3/4". Spindle speed 3,600 RPM. Equipped with: 1 HP - 1,725 RPM Motor. (2) Pneumatic hold-downs. Foot pedal control.