704-841-2001

Backed with a massive machinery database considered to be “the blue book” of woodworking machinery), EX-FACTORY Auctions provides a complete assessment of your equipment and allows you to interact with the market real-time in our dynamic Online Auction!

Industry

Woodworking

1910 Results Found

704-841-2001

CAM-WOOD BR-2732X Boring Machine32-Spindle boring head on 32 mm centers with position indicator.Features & Specifications: -- Stops in 0° & 90° with pneumatically assisted positioning in vertical & horizontal. -- 0" - 3" Adjustable drilling depth with speed control. -- Head height fine adjustment with mechanical digital readout. -- (2) 2 HP - 3,400 RPM Motors. -- Cast iron 45" x 31-1/2" table with side fences for mirror-image. -- Line boring fence with repeat stops. -- Foot actuated pneumatic clamps & drill cycle.Complete with: -- Magnetic starter, overload protection. -- Optional quick-change chucks $28.00 ea.

CAM-WOOD BR-3532X CONSTRUCTION BORING MACHINE35-Spindle boring head on 32 mm centers with position indicator.Features & Specifications: -- Stops in 0° & 90° with pneumatically assisted positioning in vertical & horizontal. -- 0" - 3" Adjustable drilling depth with speed control. -- Head height fine adjustment with mechanical digital readout. -- (2) 2 HP - 3,400 RPM Motors. -- Cast iron 52" x 19-1/4" table with side fences for mirror-image. -- Line boring fence with repeat stops. -- Foot actuated pneumatic clamps & drill cycle.Complete with: -- Magnetic starter, overload protection. -- Optional quick-change chucks $28.00 ea.

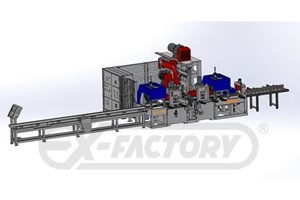

CAM-WOOD Continuous in-line Long Board Vertical Finger Joint System, Model "UCT-210"Up to 210 mm (8") Wide x 75 mm (2.95") Thick x Unlimited Assembled Length System Specifications: -- Incoming board lengths from 39"; to 118" (1,000 mm - 3,0000 mm). -- Board widths from 1.96"; to 8.26"; (50 mm - 210 mm). -- Board thickness from 1" to 2.95"; (25 mm - 75 MM). -- Board out-feed length unlimited (Conveyor to be quoted separately) -- Glue type to be used: PVAC. with Standard pneumatic pump and spreader included ( For different glue then PVAC Glue pump and applicator not included) -- Board species: SOFTWOOD and HARDWOOD. -- Board moisture content: 8% to 12%. -- Infeed board qualities: Lumber runs best on Finger Jointers when surfaced on (4) sides (S4S) (Tolerance +/- .2 mm (.008"). System prefers straight boards with 90-degree corners. UCT-210 Mechanical Specifications: -- Top infeed feed rolls powered with (1) 2 HP motors. -- Bottom infeed feed rolls powered with (1) 2 HP motors. -- In-feed Inverter with (1) 5 HP motors. -- Top Shaper Spindle powered with a 30 HP motor. -- Maximum Cutterhead length, 8.2“(210 mm). -- Maximum Cutterhead diameter, 7"“(180 mm). -- Typical cutter pitch, 4.0 mm. Length, 10 mm - 12 mm (Other sizes available). -- Shaper spindle moving power by 2.6 HP Servo Motor. -- In-feed speed from 32 to 195 FPM (10 ~60 m/Min). -- Outfeed cut-off saw motor, 5 HP. -- Cut-off sawblade, 14“ dia x 120 teeth (included). -- Cut-off sawblade speed, 2,850 RPM. -- Hydraulic pump power, 30 HP. -- Top outfeed feed rolls powered with (1) 2 HP motors. -- Lower outfeed feed rolls powered with (1) 2HP motors. -- Out-feed Inverter with (1) 5 HP motors. -- Glue injection Glue Applicator for Standard PVAC glue. Infeed/Outfeed options: -- Infeed power roller conveyor 6000mm (236") long Additional: $ 8390 -- Outfeed powered roller conveyor 15,000 mm (48') long Additional $ 43,890Optional Automatic 20 ft Cross InfeedPower Conveyor System Working size L = 1000 MM ~ 6000 MM, W= 50 ~ 305 MM, T=25 ~ 110 MM ( Lenght 39" - 236" X Width 2" -12", Thickness: 1" to 43.3")Infeed roller Conveyor 3 HP1Cross feeding system 3 HP1Feeding speed of 15 M/min (48'/min.)Storage area width 2500 mmAdditional cost: $61,990 -- Outfeed roller conveyor 20'' X 8' long Additional: $ 4,890 per sectionNot included with the machine: -- Cutter heads for finger jointer (we can provide quote) -- Gluing system with pump and nozzle if different then PVAC glueGlue pump Option: -- Graco 1K PUR Glue System Additional cost: $ 48,990NOTE: Training, installation & tooling not included TO BE PROVIDED LOCALLY -- Electric power supply to Motor Control Center -- Constant voltage (voltage deviations max.: 5%) -- Temperature range for computer control should not exceed 95°F. -- 65% Maximum relative air humidity for computer control system --Dust exhaust system: (V=30M/S at a low pressure of 12M BAR) --Compressed air connection to machinery: 7~8 KG/cm² – 8 BAR --Electrical c

CAM-WOOD RS-DW2400X 8' Overhead Rail Saw w/ Bevel CuttingFeatures: -- Programmable cutting cycle for higher production output -- 45 to 90 degrees tilting angle cutting. -- Variable Cutting Speed by Inverter. -- Rail is treated hardened, precision ground for maximum wear resistance and slide accuracy. -- Saw head runs on ball bearings giving effortless and smooth movement -- One piece casting iron arm for durability usage — heavy sheet metal stand. -- Quick tilting positions stop at right-hand 45º -- The Saw head is firmly set at any angle desired. -- Safety saw blade guard. -- Anti-kickback attachment included. -- Full-power industrial motor for durability usage. -- Overload protection switch.Available in sizes from 4' to 14' width capacitySpecifications: -- 8' Max cutting length -- 5-1/8" Max cutting thickness -- Saw blade speed 2.900 RPM -- No. of Head Travel Bearings, 8 -- Spindle dia. 1" -- Motor; 7.5 HP, 3 Ph, 230 V -- Hold down cylinders ( psc ) 3, Front & 3 Rear -- Width od table 50" -- Head Swiveling ( Horz ) 45 - 90 degreeOptional: Three of the Roller Tables; $599.00, each 4 ft Length

CAM-WOOD XCL-59 Auto Copy Lathe. via a template. SPECIFICATIONS: --Max. Between Center: 59". --Max. Finish Product Dia: 4-1/4". --Spindle Speed: 2,000 ~ 6,000 RPM. --Main Motor: 7.5 HP. --Hydraulic Motor: 3 HP. --Template Copier: One. --Model Copier: One. --Max. Copier Travel: 3-1/8". --Total Cutting Knives: 4 (including top plunging knives) --Feed Speed: Variable. --Includes (2) top plunging knives which can hold profiled or flat knives for dowel ends, etc. --Operation Modes: Manual Semi-auto, Auto. --Gross Weight: 3,400 Lbs, Net Weight: 2,900 Lbs.FEATURES: • Suitable for small quantity and multiple style production uses.• Can use sample or template for duplicate productions.• Cutter carriage forward and backward movements are hydraulically operated with feed.speed control, providing a smooth motion and stable cutting performance.• Adopts the precision hydraulic copy unit, most forms can be duplicated.• Easy to operate and lower maintenance costs.• There is a tongue shaving knife to pre-cut and guide ring to support the workpiece whencutting. This enables the cutting performance to be stable and more accurate.• Equipped with two sets of copying devices; one is copying device, which is driven by links andadopts U-Cutting tools. The other one is sample copy device by hydraulic system and adopts V-Cuttingtools.• Equipped with material center setup rack and automatic lubricator to lubricate the slide waysand keeps the slide ways in the optimal lubricated condition.• Industrial full power motor for maximum cutting capacity.• Precision sealed long-life bearing.• Heavy cast iron frame and table for durability usage.

$198,900

CAM-WOOD WP-16L- V5HX 4 Sided 5 Heads High Speed Planer Designed for furniture, cabinet, flooring, intermittent planning mill work, and other industrial uses. Perfect Planer for S2S and S4S planning, tongue & groove flooring, wall paneling, etc. up to approximately 180 FPM depending on depth of cuts and dimensions of partsSpecifications: -- Width: ¾"; to 16"; -- Height: 3/8"; to 4"; -- Length: Maximum Unlimited, Minimum 70";. -- Maximum Cutting Depth; 8 mm -- Feed Rate 40 to 180 fpmFeatures:Horizontal Top & Bottom with Slip-On Spiral Head or Optional Profile cutter head, Tooling Information. -- Standard supply with Slip-On HAR Series Profile / Spiral Cutter head, Profile Knives combined with Carbide Insert 15 x 15 x 2,5 mm. Max depth of cut 8 mm each side (Standard 7"; O.D. Shaft 46 mm): Vertical with Helical or Optional Profile cutter heads -- Left & Right Side/ Standard HAR Series Vertical profile heads. -- Max depth of cut 8mm, 7"; OD, Spindle arbor diameter: 40 mm, -- Left & Right-side Heads can be profile work with owner provided tooling. Fifth head for moulding or sawing -- 15 HP Top Saw Head, raise/lower power digital by HMIQuality Features: -- Simple touch screen with Digital Positioning Controllers for width, thickness adjustment and variable feed speed. -- Hard Chrome plated table for long life -- Automatic top spindle – cutter head height adjustments entered via HMI touch screen control with PLC. -- Floating bottom infeed rolls for smooth, positive feeding -- Variable feed speeds by VFD. Controlled from touch screen. -- Heavy-duty spindle assemblies for durability & smooth finishes. -- Overhead assembly travels up/down and positions via touch screen control, Assembly is support by (4) hard chromed, polished posts and precision screws. -- Tables, fences, etc. are precision ground, polished and hard chromed to provide long life and smooth feeding. -- Massive, heavy-duty sheet metal frame for vibration absorbing finishes and extra-long bearing life. Compact construction with exclusive see-through top guard. -- Motor Control Center with under voltage and overload protection. UL and CSA labeled electric components.Motor Sizes and Feed Works: -- Top and Bottom Cutter Heads Motors each: 30 HP, 5,000 RPM -- Right & Left Side Cutter Motors each: 25 HP, 5,000 RPM -- Second top head for Top saw head, raised and lowered motorized digitally by HMI, drive motor 15 HP -- Variable Feed speeds from 40 to 180 FPM by VFD (invertor) -- Feed is powered by (2) each 5 HP VFD feed motors, (1) motor drives the top infeed and (1) Motor drives the top outfeed feed rolls. Top powered feed rolls are air cylinder loaded / Floating. (4) idle bottom infeed feed rolls and (4) idle bottom outfeed rolls.Overall dimensions: 167" X 71" X 73".

$191,200

CAM-WOOD SM-545 HS 5-Heads High-Speed Trough Feed /Planer/Moulder(5) Heads (B-R-L-T-T), working cap. 450 mm X 160 mm (17-7" x 6-1/4").Specifications: -- Max/Min working width 17.7" - 3/4" -- Max/Min thickness 6 1/4" - 5/16" -- Minimum length 9-1/2" -- Head sequence: Bottom 15 HP, right 15 HP, left 15 HP, top 20 HP, and top or bottom 20 HP . -- All Horizontal spindles have outboard bearings -- Spindle dia. 50 mm with cutterhead speed of 6,200 RPM. -- All spindles are equipped with mechanical digital readouts, "Dual mechanical" readouts on the left and top spindles. Mechanical readouts for pressure elements and chipbreakers; all chipbreakers and pressure elements with pneumatics. -- Feed works: Inverter driven 15 HP feed system with feed speeds of 20 - 260 FPM. -- Infeed table 2M (6'6"), chromed tables, and fences. Side pressure roller mounted at infeed. Features and complete with: -- Feed speeds ranging from 20' ~ 260' per minute are a standard feature. -- The full safety enclosure also works as a chip guard and helps to reduce noise. -- Table surface is hard chrome-plated for maximum wear resistance. -- All manually adjusted turning parts are housed in dry bearings for oil-free lubrication. -- One piece cast iron machine frame and table is especially normalization heat treated for maximum stability and rigidity. -- Fence adjustment is quickly accomplished by a quick-setting lever. -- The three independent section pneumatic pressure for the infeed rollers, in-process rollers and outfeed rollers can be set with individual pressure allowing for consistent feeding results and outstanding effect. -- All control levers for the spindles are located at the front of the machine for convenient adjustment. -- Each spindle is provided with a mechanical digital readout, giving accurate adjustment. -- Vertical spindle adjustment up to 80 mm, allows fitting several tools on the vertical spindle, eliminating troublesome cutter change. -- Separate adjustment of vertical spindle and insert table permits the table to be positioned extremely close to the cutterheads for added cutting stability. -- An individual motor drives each spindle and is separately mounted to eliminate spindle chattering during high-speed running. -- Centralized lubrication system Available options: -- Digital (electronic) display for X and Y axis for each head add $ 3,200 /per head -- NC Automatic positioning control system. This option consists of motorized adjustment of the head control from the main screen of the machine.This option include: -- 15" HMI (1000 memory setting), -- Servo motor positioning, Simple and easy to operate. -- Width and thickness quickly & auto set-up -- Tools management system -- Lateral chain feeder (quoted with customer material specifications)

$62,900

CAM-WOOD WS-NDA 1300 3 Head Planer Sanderequipped with Planer, Drum and combi headFeatures: -- This machine is especially designed for tale off heavy material such as glue panel, bend board, rough lumber. -- The first station is a knife planer head, followed with a combi head with drum and platen at second station, and finishing platen head at third station. -- Head configuration can be made to meet customer’s requirement. -- The spiral planer cutterhead is fitted with 14 x 14 MM, four edge throw away Tungsten Carbide knife inserts, providing superior chip removal rate, minimum noise, and extremely smooth cutting effect. -- Changing knife inserts are conveniently done without removing the cutterhead. The spiral cutterhead is precision machined from special aluminum alloy steel by CNC machine center, tempered and precision ground. -- Anti-kickback fingers, mounted at the infeed of the machine, this anti-kickback finger gives a safety guard for the operator. -- Insufficient pressure protection, in case insufficient working air pressure occurs, the machine brakes automatically for safety guard. -- Irreversible running of pressure roller, runs a single direction only, giving an additional safety guard for panel kickback. -- Automatic elevation of conveyor table (micro-computer controlled with digital readout), it accurately displays the position of the conveyor table and automatically moves to the setting thickness for planning, sanding. -- Panel cleaning brush roller; built at outfeed end of the machine, this cleaning brush roller cleans the powder on the sanded panel. -- Hold-down plate is hard chrome treated for maximum wear resistance.Specifications: -- First head Planer with 40 HP motor -- Second head combi drum & platen with 30 HP motor -- Third head finishing platen with 30 HP motor -- Panel cleaning brush at outfeed with 1/2 HP motor -- Working width: 52" -- Working thickness up to 6 1/4" -- Minimum working length: 21" -- Feed speed 10 FPM to 90FPM inverted driven by 5.5 HP motor -- Table hoist motor 1 HP -- Sanding belt size 52" X 75" -- Floor space requirement: 107" X 103" X 80" weight 12,300 lbs

$24,990

CAM-WOOD EB-L5 EDGEBANDER0.4 mm - 3 mm Edgebanding thickness capacity, 10 mm (3/8") - 50 mm (1.96") material thickness capacity, 63.5 mm (2.5") minimum part width, 160 mm (6.3") minimum part length. Equipped with: -- Automatic feed of coil banding and semi-automatic strip fed magazine (strips 1- 3 mm max.) with 3 mm PVC cap. guillotine. -- Teflon coated glue pot w/fast (10 - 12) Min heat-up time; 4-liter capacity. -- Guillotine to cut edgebanding in coils up to 3 mm thick. -- Pneumatically controlled pressure section with (3) pressure rollers; 1st drive, (2) idle.Workstations: -- Double Motor end trimming saw unit with (2) 1 HP (0.75 kW) - 12,000 RPM High-Frequency motors. Cutting group moves on rounded ways made of hardened steel, to guarantee high precision and reliability; cutting movement from the top of the panel. -- Top & Bottom Trim station with: (2) 0.75 HP (0.56 kW) - 12,000 RPM High-Frequency motors; unit features adjustable copying on vertical & horizontal floating movements, adjustable cutterhead position by mechanical digital readouts, quick release (electrical & mechanical). Includes (2) 3 mm radius cutters. -- Top & Bottom Buffing unit with (2) 0.50 HP (0.37 kW) - 1,400 RPM motors. Feed & Holddown: -- Feed rate of 12 MPM (40 FPM); feed chain pads with replaceable rubberized surface inserts. -- Special design "track frame" to eliminate feed chain side-to-side movement after years of use. -- Rubberized holddown rollers with ball bearings for low friction and long life. -- Complete with: Sound enclosure protects the operator from noise and debris.

Call for Price

CAM-WOOD HSTC-62 HIGH SPEED LONG BOARD VERTICAL FINGER JOINTER with the following Specifications: HSTC-62A Infeed Belt Conveyor: -- Working dimension: 24"; wide x 16’ long -- Speed at 110 FPM -- One 3 HP Inverter Drive Motor SHAPER #1: DFSR-62I - Left Side Heavy Duty Finger Joint Shaper -- Working dimension: 24"; wide x 1"; to 10"; high x 8"; to 16' long -- Scoring Saw: 2 HP motor -- Scoring Saw Blade: 7"; diameter x 50 tooth -- Scoring Saw speed: 2,850 RPM -- Trim Saw Spindle: 15 HP motor -- Trim Saw Blade: 12"; diameter x 80 tooth -- Trim Saw Speed: 2,800 RPM -- (2) Finger Joint Spindles, (1) for rough cut and (1) for finish cut, each with a 30 HP motor -- Spindle diameter: 50 mm -- Diameter of cutterhead possible without knives: 8-1/4"; -- Shaper Spindle speed: 3,800 RPM -- Conveyor belt with 3 HP Inverter Drive -- Table cycle by 3 HP Drive Motor -- Table cycle speed from (1) to (4) cycles per minute (depends on work)HSTC-62A HEAVY SINGLE TABLE OUTFEED TRANSFER CONVEYOR -- Working dimension: 24"; wide X 16’ long -- Speed at 110 FPM -- One 3 HP Inverter DriveHSTC-62A SINGLE TABLE INFEED TRANSFER CONVEYOR -- Working dimension: 24"; wide X 16' long -- Speed at 110 FPM -- One 3 HP Inverter DriveSHAPER #2: DFSR-62I - RIGHT SIDE HEAVY DUTY FINGER JOINT SHAPER WITH GLUE APPLICATOR -- Working dimension: 24"; wide x 1"; to 10"; high x 8"; to 16' long -- Scoring Saw: 2 HP motor -- Scoring Saw Blade: 7"; diameter x 50 tooth -- Scoring Saw speed: 2,850 RPM -- Trim Saw Spindle: 15 HP motor -- Trim Saw Blade: 12"; diameter x 80 tooth -- Trim Saw Speed: 2,800 RPM -- (2) Finger Joint Spindles, (1) for rough cut and (1) for finish cut, each with a 30 HP motor -- Spindle diameter: 50 mm -- Diameter of cutterhead possible without knives: 8-1/4"; -- Shaper Spindle speed: 3,800 RPM -- Conveyor belt with 3 HP Inverter Drive -- Table cycle by 3 HP Drive Motor -- Injection type adhesive spreader with standard glue height of 10"; -- Glue system included is for PVAC. -- Optional APQUIP Glue System available at extra cost -- Optional Glue Equipment available for Loctite HB X Glue at extra price -- Deduct ...$5,200 if provided without a Glue SystemHSTC-62B OUTFEED CONVEYOR WITH BELT CLEANER -- Working dimension 24"; long X 16’ wide -- Speed at 115 FPM -- (1) 3 HP Inverter Drive -- (1) 1/2 HP motor for conveyor cleaning device HSCB-62 TIPPING CONVEYOR W/NARROW CONVEYOR -- Flips boards from vertical to horizontal for automatic feed to the Press -- Working dimensions: -- (1) Conveyor at 24"; wide x 16’ long -- (1) Conveyor at 8"; wide x 16’ long -- Speed 110 FPM -- 3 HP Inverter Drive UFJ-600 FINGER JOINT CONTINOUS ASSEMBLY MACHINE FOR INFINITE LENGTHS -- Working dimension 1-3/8"; to 10’ wide X 1"; to 4"; thick by unlimited lengths -- In-feed speed from 100 to 165 FPM -- Cut-Off Saw: 7-1/2 HP -- Cut-Off Saw Speed: 2,850 RPM -- Cut-Off Saw blade dimensions: 18"; diameter x 1"; bore x 120 tooth carbide tipped -- Hydraulic Pow

CAM-WOOD SFJ-3800-205-FM-FAH HIGH SPEED, LONG BOARD, HORIZONTAL JOINT, FINGER JOINTER: Specifications: -- Double Chain & Slat Type Shaper Section designed for long incoming boards -- Manual infeed; Slat Bed Feed Chain runs at up to 75 FPM; lugs on 30" centers. Slat Bed powered with a 15 HP gear motor with 1:40 gear ratio. -- Table Transfer Conveyor (Powered), even ends boards to the Right and Left Shaper Fences: powered by (2) 7-1/2 HP motors -- Power raising and lowering of the holddown assemblies on both Shaper Sections; Powered with (2) 2 HP motors -- (1) Pair Scoring Saws with 2 HP motors, 50mm arbor, 2,850 RPM, scoring blade size of 7"; x 50 tooth, (4) Blades included -- (1) Pair Trim Saws with 10 HP motors, 50mm arbor, 4,275 RPM, trim saw blade size of 10"; x 100 tooth. (2) Blades included -- (1) Pair Vertical Hogging Shaper Spindles with 10 HP motors, 50mm arbor, 4,375 RPM, hogging blade size of 9.4"; x 50-tooth. (2) Blades included -- (1) Pair Vertical Finish Shaper Spindles with 20 HP motors, 50mm diameter spindles, 5,300 RPM. For -- 50mm bore x 160mm dia. cutterheads; finger length of 1.122";; cutterheads and knife profile to buyer’s specification -- Extrusion Type Glue Application System for PVAC Glues; mounted on Right Side Shaper Section. Includes glue pump, valves, and glue injection thru the applicator comb machined to buyer's specifications. -- Optional APQUIP Glue System available at extra cost -- Optional Glue Equipment available for Loctite HB X Glue at extra price -- Deduct $5,200 if provided without a Glue SystemSCC-20 TRANSFER CONVEYOR -- Conveyor between Shaper Section to the Press Section -- Working dimension: from 1"; to 8"; wide x 12"; to 12’-6"; long -- Speed 230 FPM -- Powered by (1) 3 HP HSC-65 HIGH-SPEED PRE-PRESS ASSEMBLY SECTION -- Working dimensions: 1"; to 8"; wide x 3/4"; to 2-1/4"; high x up to 21’ long -- (2) 5 HP motors drive the double flat-top chains -- Feed speeds from 32 to 295 FPM -- Includes (1) 15 HP Frequency Converter to power the feed chain motors at speeds determined by incoming boards lengths NFJ-1500 50’ HEAVY-DUTY AUTOMATIC ASSEMBLY PRESS -- Working dimension: 1"; to 8"; wide x 3/4"; to 2-1/4"; high x up to 50’ long -- Power of upper rollers: (2) 3 HP motors with a 1:10 gear ratio -- Power of lower roller: (1) 5 HP motor with a 1:10 gear ratio -- In-feed Inverter: (1) 15 HP motor -- In-feed speed: From 32 to 295 FPM -- Cut-off saw: With 7.5 HP motor driving the arbor at 2,850 RPM -- Sawblade: 14"; Diameter x 120 tooth -- Hydraulic power to the Pressing Cylinders: (2) 20HP with high-speed oil tank -- Hydraulic pressure output: 1,700 PSI at the joint -- Capacity (1) to (4) 50’ assembled boards per minute -- Machine comes arranged with equipment to assemble (3) sizes of material cross sections according to buyer’s specifications for width within +/-3/16"; width toleranceSYSTEM REQUIREMENTS FOR INCOMING BOARDS -- Incoming lumber length: 1’ to 12

CAM-WOOD SFJ-460L FINGER JOINT ASSEMBLY PRESS SYSTEM With Optional GluingDescription: -- The SFJ-460L is an automatic Assembly System, Cutoff Saw, and Press. The system performs three functions; pre-assembles finger jointed blocks with glue previously applied in the FSG 150 manual Glue Applicator (not included), cuts the assembled boards to length, and performs the final assembly when pressed by a powerful hydraulic system. When pressing is complete, boards are fed out of the Press. -- Power feed for feeding boards, stops automatically at the desired board length using the included cut-off saw as standard equipment for cutting boards to length. -- The maximum assembled board length is 15'. Specifications: -- Max. length capacity, 188"; max. width, 6"; max. thickness, 3". -- Feed speeds from 0 - 26 FPM; -- Cutoff Saw runs at 3,500 RPM and is powered by a 5 HP motor; Blade diameter is 355 mm (14") with a 1" arbor; -- With 1/2 HP feed motor and 5 HP hydraulic pump motor. Option: -- Manual Gluing unit FSG 150 Additional $ 8,990Note: Same press with 6,000 mm (19.7') capacity additional price is $6,900

CAM-WOOD TYPE F1, MODEL FAH, 6"; X 20’ Horizontal Fully Automatic Finger Joint System Single Chain TypeMECHANICAL SPECIFICATIONS FOR THE FEED SYSTEM: -- Operating speed: 120 to 150 lugs/Min -- Intermittent feed motor: 2 HP + 1:25 -- Feed chain motor: 30 HP (20 kW) Servo Drive (C2) MECHANICAL SPECIFICATIONS: RIGHT-SIDE SHAPER: -- Cutterhead Motor: 25 HP -- Spindle size: 2-3/4"; (70 mm) -- Maximum cutter head body diameter: 10"; -- Cutterhead speed: 5,500 RPM at 60 Hz -- Trim Saw Motor: 15 HP -- Trim Saw blade size: 12"; (305mm) x 80 Tooth x 5mm kerf -- Cut-off saw Speed: 4,300 RPM -- Scoring saw motor: 3 HP -- Scoring saw blade: 7"; (180 mm) x 50 Tooth x 5 mm -- Scoring saw spindle speed: 4,200 RPM -- Holddown rise and lower motor: 1/2 HP (C3) MECHANICAL SPECIFICATIONS: LEFT-SIDE SHAPER: -- Cutterhead Motor: 25 HP -- Spindle size: 2-3/4"; (70 mm) -- Maximum cutter head body diameter: 10"; -- Cutterhead speed: 5,500 RPM at 60Hz -- Trim Saw Motor: 15 HP -- Trim Saw blade size: 12"; (305 mm) x 80 Tooth x 5 mm kerf -- Cut-off saw Speed: 4,300 RPM -- Scoring saw motor: 3HP -- Scoring saw blade: 7"; (180 mm) x 50 Tooth x 5 mm -- Scoring saw spindle speed: 4,200 RPM -- Holddown rise and lower motor: 1/2 HP -- Glue Application by GLUE COMB -- Standard glue height: 6"; High, 3.8 mm pitch 3.8 mm. Finger lengths from 10 to 12 mm (Other lengths available) (K) MECHANICAL SPECIFICATIONS: SHAPER OUT-FEED: -- Speed: 230 FPM -- Feed Motor: (1) 3 HP -- Vacuum device blower with 3"; Vacuum port: 5 HP (G) MECHANICAL SPECIFICATIONS: PRE-JOINT ASSEMBLY: --Feed chain drive: (2) 3 HP motors --In-feed Inverter: (1) 7-1/2 HP --Chain type: Flat top double chain --Feeding speeds from 30 to 300 FPM (H) MECHANICAL SPECIFICATIONS: 20’ (6.2M) ASSEMBLY PRESS: --Working dimension: 3/4"; to 6"; wide x 0.60"; to 3"; high x up to 20’ long --Upper & lower roll power: (2) 2 HP motors --In-feed Inverter: 7-1/2 HP --In-feed speed: 30 to 300 FPM --PROGRAMMABLE Cut-off saw power: 5 HP --Cut-off Blade dimensions: 14"; Dia. x 120 Tooth x 1"; bore --Cut-off saw speed: 2,850 RPM --Hydraulic power: 5 HP (With high speed oil tank) --Cycle Speed: 1 to 8 Cy/MinPRODUCTION CAPACITY - PARAMETERS: -- Based on a 480-minute shift -- Finger length to customer’s specifications -- Average infeed length at the shaper section is 20"; --A verage block cross section is 2"; x 4"; -- Chain speed at the Shaper sections is 150 lugs/Min -- Press capacity is (8) 20’ loads per minute (maximum) CAPACITY OF THE SHAPERS WHEN FINGER JOINTING 2"; X 4"; x 20" BLOCKS -- (120) Blocks per minute -- x 20"; Average infeed length -- x 480 Minutes per shift -- x 0.8 Rate of utilization = 76,800 lineal feet per shift CAPACITY OF THE PRESS ASSEMBLING 20’ LENGTHS: -- (8) Assembled lengths per minute -- x 20’ Per minute -- x 480 Minutes per shift -- x 0.8 Rate of utilization = 66,440 lineal feet per shift -- NOTE: If using the cutoff saw for multi-section pressin

TRS-460M4 Multiple Blade Rip Saw w/Optimizing, (4) SHIFTING BLADES ● WITH 18" OF USEABLE ARBOR SPACE!Specifications: -- Moveable sawblades when using the Optimization program.1-1/2"; minimum distance between movable saw blades -- Sawblade configuration with (4) movable saws and (1) fixed sawblade -- Sawblades are optional -- Infeed & outfeed roller tables are optional -- With 50 HP saw arbor drive motor and 3 HP feed motor -- Pressure rollers elevation motor: 1/2 HP -- (4) 1 HP servo motors for shifting sawblades -- Fence adjustment is manual. -- (4) 0.13 HP servo motors for shifting Laser Lights -- With (5) Laser Lights -- UL electrical components. -- 10 to 130 FPM variable feed speed -- 18"; Max. distance between fixed saw and the last (outside) movable saw -- 31"; Max. material feeding width -- 27"; Min. cutting length -- (2) 6"; Dust hoods -- Cutting depths: 10" blade, 1.65"; thick ; 12"; blade, 2.65"; thick; 14", 3.66"; thick; 16" blade, 4.64"; thick -- Sawblade size vs. RPM. Make Blade size clear when order) -- Spindle speed @: 3,800 RPM (10" & 12"sawblade) / 3,000 RPM (14" & 16"sawblade)Computerized Rip Optimizing Program, Included: -- The operator only sets a line for total width, then the computer performs optimized ripping according to sizes set on the job sheet and the priority mode set from these options: -- 1. Priority according to the widest -- 2. Priority according to the same size -- 3. Fixed-width ripping -- 4. Yield priority -- 5. Value priorityOPTIONAL MODEL TRS-460M4-INCOV 3500mm AUTOMATIC INFEED CONVEYOR SYSTEM WITH SCANNER AND OPTIMIZING SYSTEM, add $198,000 -- Automated infeed system, speed rate controlled by electrical clutch connected with the Ripsaw's feed chain -- 13' max. infeed length with (16) width detectors (scans every 8") -- Special pressure roller set, motion with liner rail and air cylinder -- Width scanning by sensors, with optimizing program for auto calculating -- Moving fence by servo motor, according to the wood width

CAM-WOOD MODEL TRS-3000TB.12" SLAT RIPPER - (1) top & (1) bottom rip spindle.CAM-WOOD MODEL TRS-2050TB.8" SLAT RIPPER - (1) top & (1) bottom rip spindle - DEDUCT $8,000 for the 8" Cap. modelFEATURES: -- The machine can plane or shape the wood at two surfaces and then rip it. Ideal for shutters, louver slats, yardstick blanks, etc.. -- Special profile hold down & groove table for slat ripping, optional -- Designed to meet the exacting standards required for high-quality production line use. -- CAM-WOOD’s Slat Rip Saws are manufactured to precise tolerances and feature the newest designs for operator safety and volume production. -- All of these features combine to show the true value of these machines in today’s highly competitive market. -- Precision fence assures absolute accuracy between cutterheads & fence and is equipped with a measuring gauge. -- Double anti-kickback fingers mounted at the infeed end of the machine provided maximum safety protection. -- Heavy-duty industrial TEFC motor ensures full-depth cutting capacity in all materials. -- Ruggedly constructed steel frame for durability and extended machine life. -- The variable speed feed works allow the machine to meet the cutting requirements of different materials. -- Saw heads built to precise tolerances assure accuracy for all ripping and profiling operations providing a stellar cut quality. -- Top & bottom powered pneumatically tensioned pressure rollers for precise feeding and cutting. -- Saw arbor is manufactured from alloy steel for dependability and anti-fatigue, heat treated, precision ground, and balanced providing precise cutting performance.SPECIFICATIONS: -- 12"; Max. Cutting Width (TRS2050 WITH 8" MAX. WIDTH) -- 4-3/4"; Max. Cutting Depth -- Min. Cutting Depth Limited by Thin Material Breakup -- 10"; Min. Workpiece Length -- 14"; Dia. Max. Sawblade Size on Top Spindle -- 10" to 16"; Dia. Sawblade Size on Bottom Spindle (TRS2050 WITH 16" DIAMETER) -- 4,000 RPM Top & Bottom Spindle Speed -- 12"; Spindle Length (TRS2050 WITH 8" SPINDLE LENGTH) -- 40mm Arbor Diameters with 2-Keyways (TRS 2050TB WITH 70MM ARBORS) -- 15 HP Top Rip Saw Motor (TRS 2050 WITH 10 HP MOTOR) -- 30 HP Bottom Rip Saw Motor -- (6) Upper and (2) lower Feed Rolls -- 12 to 60 FPM Feeding Speed (Variable) -- 1 HP Feed Roll & Top Head Elevating Motor -- 1/2 HP Lower Saw Arbor Elevating Motor -- 7-1/2 HP Feed Motor (TRS2050 WITH 3 HP MOTOR) -- Dimensions (L x W x H) 96" x 64" x 55"

CAM-WOOD DC-07 STA Cyclone Dust Collector w/ After-filtersNew designed two-stage cyclones. As the “dirty"; air stream enters the collector, the heavy particles are separated by cyclonic action and fall to the bottom storage bag. The remaining air stream with fine dust goes through the impeller, it can increase dramatically the life of the impeller & motor preventing damage from large material.Features: -- 7.5 HP blower with 4,200 CFM. -- Inlet Diameter 12" x 4" x 5. -- Heavy sheet metal frame and base. -- Extra-large radial-fin type steel impeller for high-efficiency airflow. -- Heavy duty totally enclosed industrial motor for maximum air suction and extended service life. -- Quick-release clamps are used to tighten the bags; this helps to reduce downtime when doing maintenance. -- Low sound levels to keep the working area quiet. -- Includes: (2) Collection drums

CAM-WOOD DC-102-3X Dust CollectorSmall radial-finned Dust Collector mounted on wheels for portability.Features & Specifications: -- Large 13-1/2" fan that produces 2,100 CFM. -- Heavy Duty 3 HP motor pre-wired at 460 Volts. -- Large capacity dual station cloth top bags of 31.2 sq. ft. total cloth filter area. -- Low sound level of 75 - 90 dB.

CAM-WOOD DC-8100X Dust Collector Radial-finned type impeller for the best efficiency with large 15-3/4" dia. fan that produces 7400 CFM.Includes: -- Heavy Duty 10 HP motor pre-wired at 230 V. -- 10" Inlet -- (4) Large top filter bags and (4) lower collection bags with 48 cu. ft. capacity. -- Standard steel spring clamps to secure bags without leakage.Features: -- Low sound level of 75 - 90 Db keeps the work area quiet. -- Optional connection for using collection barrels.Note: 230 or 460 Volt, 60 Cy, 3-Ph please advise.

CAM-WOOD DC535 DUST COLLECTOR 2900 CFM5 HP Motor and 14" Dia. Radial-fin type steel impeller to get the best efficiency usage.Specifications: -- Two top filters and two collection bags. -- Heavy-duty motor for powerful operation. -- Larger size impeller and extra long top air exhaust bags enabling to collect sawdust and wood chips more easily. -- Standard steel spring clamps to secure the bags with the body without leaking dust. -- Low sound levels keep the working area quiet. -- Replacement bags or 5 micron bags for fine dust are available. Optional connect bags for barrels are available.

CAM-WOOD DC-10 STAX Cyclone Dust Collector w/ After-filtersNew designed two-stage cyclones. As the “dirty"; air stream enters the collector, the heavy particles are separated by cyclonic action and fall to the bottom storage bag. Then the remaining air stream with fine dust goes through the impeller, it can increase dramatically the life of the impeller & motor preventing damage from large material.Features: -- 10 HP blower with 5,000 CFM. -- Inlet Diameter 13" x 4" x 5. -- Heavy sheet metal frame and base. -- Extra-large radial-fin type steel impeller for high-efficiency airflow. -- Heavy duty totally enclosed industrial motor for maximum air suction and extended service life. -- Quick-release clamps are used to tighten the bags; this helps to reduce downtime when doing maintenance. -- Low sound levels to keep the working area quiet. -- Includes: (2) Collection drums