704-841-2001

Backed with a massive machinery database considered to be “the blue book” of woodworking machinery), EX-FACTORY Auctions provides a complete assessment of your equipment and allows you to interact with the market real-time in our dynamic Online Auction!

Industry

BioMass

211 Results Found

704-841-2001

EDGE - VS420, ...Mobile Shredder: ...Less than (1,400) Hours. Features & Specifications: --Year: 2021 -- Make: EDGE. -- Model: VS420. -- Trim: Scrap Processor. -- Hours: 1,350. -- Green Waste Shafts. -- Powered via a CATERPILLAR C9.3B - Tier 4 Final / STAGE V - 310 kW (420 HP) Engine. -- Twin Shaft design provides exceptional intake behavior, less wear, self-cleaning, and prevents material wrapping. -- Intelligent self-protecting control system.Applications -- All types of wood (railway sleepers, pallets). -- C & D (construction & demolition). -- Green waste (including grass, trees, stumps). -- Domestic and household waste. -- Commercial and industrial waste. -- White household goods. -- Paper and cardboard (including paper rolls). -- Mattresses. -- All plastics (including wind turbine blades).

Call for Price

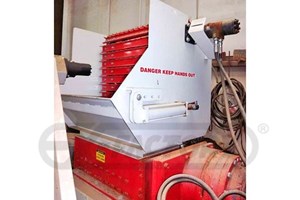

EIDAL Model 125 Dual Shaft, Slow Speed High Torque Shredder; 125 HP drive motor; 54"x44 " cutting chamber, cutting disc width approximately 2.5" thick. -- The rotor shafts are directly coupled to the 125HP motor through a heavy duty gearbox, 415 RPM rotor speed. -- Includes: Stand and Hopper. --Power Coupler Buna Spider insert failed and will need replaced.

ELETTROMECCANICA 365710 AUTOTRANSFORMERAuto Transformer Specifications: -- 35 KVA; 220 - 230 V; 60 Hz Primary Transformer to 380 Y+N; 50 Hz secondary.

Call for Price

Plant Boiler System for up to 60,000 pounds of steam production per hour (1790 HP) with the following features and main components: -- (2) ENGLISH BOILER AND TUBE, INC. Boilers each rated for 20,700 pounds of steam per hour each. However, manufacturer specified they can be operated at 30,000 pounds per hour with dry wood or bark fuel (12 percent moisture). -- 250 PSI operating pressure ratings on each Boiler. -- VFD Drives on all main Motors. (The plant uses a maximum 75 HP for each boiler.) -- Electrical Controls. -- (1) Boiler has an Oil Burner for operating optionally on oil if sawdust or wood chips is not available. -- Chemical Water Conditioning System and Pumping System. -- De-aerator and Condensate Tank. -- Multi-clones for particle emissions reduction and abatement. -- (2) Fuel Storage Silos (25’x40’ & 20’x38’) with LAIDIG Model 243 Track-Driven Unloaders. -- Fuel Transfer Conveyors. -- The Silos also are included at the price shown and are available individually. See our listings DB-010162 and DB-010163 for details and individual pricing. -- Boilers can be purchased individually or as a pair. -- Professional removal and installation services are available.

Call for Price

MODEL 600 - 24" BLADES" ENTERPAT Alligator Shear --Description -- MODEL 600 --Blade Length: 600mm --Cutting Force: 80 tons --Motor: 3 Phase 10HP

Call for Price

Enterprise - 16" BLADES" Alligator Shear --Blades- 16″ -- Blade Force- 133 Tons --SPM- 15-50 --Capacity: Flats- 3/4″ x 8″ Rounds- 2″ Reinforcing- 1-#14, 2-#11, 4-#8 --Motor- 10 hp 230/460 3ph

Call for Price

EVASHRED EV60E Dual Shaft Shredder with Infeed ConveyorEvashred is a well-known brand of commercial mobile and stationery shredders for solid waste designed and manufactured by F.V. Evans and Sons also known as Evans Engineering.Every type of shredder is designed specifically to shred a particular type of solid waste including Documents, Car & Truck Tyres, E-scrap (Hard Drives, Computers, Printers known as E-waste and e-scrap), Plastic, Foam rubber, Green Waste, Building Waste even Hospital WasteSpecifications: --30 kW / 40 HP Maximum Power --28-30 RPM Cutter Speed Rotation --Width 640 mm x 37 5mm Cutting Chamber Opening

Call for Price

EXCALIBUR- 1042-60, ...Dual Shaft ShredderSpecifications: -- Motor: 60 HP. -- Opening: 42x 25". -- Cutters: 1 1/8" Wide. --Includes Control Panel -- Includes Stand but no Hopper÷ Loaded onto your Truck.

EXPRESS SCALE CM-780D-II Bagging System with ConveyorsSpecifications: -- Air-operated double door weigh hopper: 3.5 CuFt -- Load cells: 100 KG (220 Lbs) -- Weigh Range: 10-110 Lbs or 5-100 kG -- Cycle Speed (simplex): 13 bpm (50 lbs or 25 kG) -- Cycle Speed (duplex): 22 bpm (50 lbs or 25 kG) -- Typical Accuracy: ±2-3 oz. or ±56-85 gramFeatures: -- 1280 Express Digital Programmable Controller with digital readout -- RS232 output -- Operator station. -- Protect individual or all parameters via pass-code protection -- Ethernet connectionSystem Equipped with: -- Gravity Feeder: High-Output Gravity Gate (13" x 8") 2-position for bulk and dribble feed. Handlingfree-flowing products such as grain, seed, and prilled fertilizers. Rated at 14-16 bags per minuteSimplex or 22-24 BPM - duplex. Typical accuracies will be +/- 2-3 ounces (56-85 grams). -- Spout Assembly: Dust Tight 21", 25", or 31" Circumference -- Hopper Surge: For simplex scale only, mild steel construction gray powder coated 40 CU' capacity(operator platform and handrail not included) 4"x 4" x 1/4" wall tube, 3/16" Metal Plate for wallsof Hopper. -- Conveyor: 22' x 18" product delivery: 2 HP Motor, 3" Scoop Cleat Belting w/ Hopper for Unloading Bulk Bags -- Bag Closing Conveyor with Air-Flo Hot Air Heat Sealer: 10' overall length, 1/2 HP motor, 12"-wide 3-ply neoprene smooth top belt, 110V variable speed motor mounted internally, adjustable conveyor height 13.5" to 18.5" and adjustable back plate, electrical controls include on/off switch.Backed by a 1 year warranty and lifetime customer support.

Call for Price

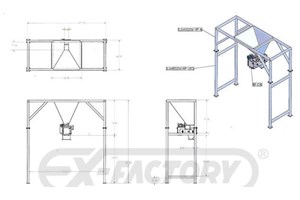

SPECIAL FEEDER FOR HAMER 2080FFS BAGGER -- Hopper 37 Cubic Feet and Support -- With Scale Support System -- Belt Feeder with Discharge to Existing Hamer Form-Fill and Seal -- Brand New -- Loaded on your Truck

Call for Price

COMPLETE LOOSE BAGGING SYSTEM System includes: -- Feed Hopper 3 Yards Capacity. ( 87 Cu.Feet) -- 24 feet Incline Conveyor. -- GB Mechanical Bagging Scale -- Feeding Hopper 37 Cu.Feet with Stand. -- Packrite Xtrol Impulse Sealer. -- Motorized Bag Conveyor. -- Loaded on your Truck.

Call for Price

EXPRESS SCALE MCRS-180ELECHYD LOOSE BAGGING LINEComplete Loose Bagging Line including the Following; -- Hopper Stand and Support 37 cu' BF/GV/AUG -- GB Bag Fill Machine -- BF-14 Belt Feeder -- Bag Closing Conveyor 510-LP -- Fishbein Sewing Machine -- Hopper 87 cu' with Support -- Belt transfer Conveyor 27' -- Loaded on your Truck

Call for Price

LOOSE BAGGING SYSTEM "MCSRE"System includes and is supplied with: -- Hopper BF 87 Cu/Ft. and Support, Charging Hopper to Integrate with product Delivery Conveyor -- CON PD 24X24: 24 Feet Product Delivery Conveyor -- Hopper Stand BF: Hopper and Support 37 Cu/Ft. Surge Hopper for 5 GV Duplex Net Weight Bagging System -- GV-52 - DUPLEX GRAVITY/VIBRATORY TRAY: Duplex unit for (20) Bags/Minute -- Spout to Meet Customer's Bag -- CON 512: Bag Closing Conveyor. 12 Feet Long -- PACKRITE XROL: Heat Sealer with Extra Set of CO.Loaded on your Truck

Call for Price

MCRS is a Bagging System for mulch, compost, rock, or sand. This system is complete with a 2-yard product surge hopper, a 20' X 24" wide troughed incline product delivery conveyor with a cleated belt, an 8' bag closing conveyor, and a custom 7.5 HP Elec/hydraulic power unit. The system can fill bags by time and depth of stream or digitally with load cells.Standard construction carbon steel Powder Coated Industrial Gray(RAL 7046).The MCRS operation has been designed for one man to bag fill, bag close, and stack three bags per minute continually. -- The operator hangs bag #1 on the scale, hits the palm switch to close the CG spout, and automatically fills it. -- Bag #1 will drop once the timer times out onto the moving conveyor and hangs bag #2 into position, hits the palm switch, and starts the filling. -- The operator steps to his left. Bag #1 contact a wand switch and is in position underneath the impulse sealer. --The operator starts the bag into the impulse sealer. Once completed, bag #1 is then manually stacked. -- Bag #2 filled and waiting for the operator's return. -- Bag #2 is then released, and bag #3 hung. -- The process is then repeated.The Front End loader feeds the system. Consists of the following --infeed hopper --incline conveyor --dosing system --bag closing system:Bag Closing System Consists of a (CON 508) 8' long x 1' wide smooth top belt to take bags into aposition where a wand switch manually stops them. The bags are then prepared and enteredinto theImpulse Sealer (31103737610) Programmable Impulse Sealer for the repeated sealing of thermoplastic films such as polyethylene and polypropylene. This automatic single-impulse heat sealer is controlled by a plug-in transistorized circuit board and electronic timers. The timed closure ensures an even and consistent seal. --THE PRICE REFLECTS AN UPGRADE FROM THE IMPULSE SEALER TO A SEWING SYSTEM.The operator has hands free to handle the product quickly. This type of machine generally increases workers' productivity.The electric foot pedal is included for manual operation. -- Seal Length: 24" -- Seal Thickness: 8 mil -- Seal Width: 10 MM

Call for Price

EZ CAR CRUSHER MODEL A+ --Opening 20 ft long x 7'6" width x 8 ft height --System Pressure 2500 psi --Port Reliefs Set At 2650 psi --Cylinders 10" bore --Travel 78" --Shaft 4" rod --Remote --Approx 5,500 Hours

Call for Price

FANUC - M-410I, ...Palletizing RobotFANUC M-410iC/110 Robot is a Palletizing Robot. It runs on the FANUC "R30iB" and "R30iB Plus" controller platform. With lighter payload, this Robot is designed to run faster than its bigger variants.This Robot was ordered and never installed, so it is "new" old stock.Max. payload: 110 kG (242 Lbs). -- Reach: 2,403 mm (94"). -- Axes: 4. -- Repeatability: +/- 0.5 mm. -- Robot Mass: 1,030 kG (2,270 Lbs). -- Floor mounted.

Call for Price

FANUC M410/160 iB ROBOT PALLETIZING SYSTEM Specifications: -- Complete with R-30iA Controller All Refurbished -- Pillow Bag Tooling -- 4-Axis control -- Mounted to a heavy-duty base -- 10 Feet Long Rubber Belt Conveyor -- (2) 5 Feet Motorized Pallet Conveyor -- (3) 10 Feet Motorized Pallet Conveyor -- Automatic Pallet Dispenser -- up to (14) 50 Lbs bags per minute -- Machine weight 4500 LbsAUTOMATIC PALLET STRETCH WRAPPING SYSTEMWULFTEC or LANTECH Stretch Wrapping System or Equivalent Not INCLUDED

Call for Price

FANUC - S430iW, ...RobotFANUC Robot for palletizing rectangular compressed bags.Specifications -- (6) Axes. -- Payload: 165 kG (255 Lbs). -- H-Reach: 2,643 mm (104"). -- Robot mass: 1,300 kG (2,860 Lbs). -- Complete with: Pendant control. -- Complete with: Gripper type arm and pallet gripper. -- Refurbished with (90) days Warranty. -- Buyer to install safety guards.NOTE: Machine was rebuilt is 2021.

Call for Price

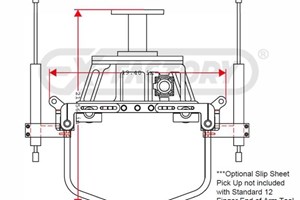

END ARM TOOLING FOR FANUC ROBOT -- Gripper Finger Type End Arm Tooling -- Design for Fanuc Robot Model S-430iW -- Loaded on your truck